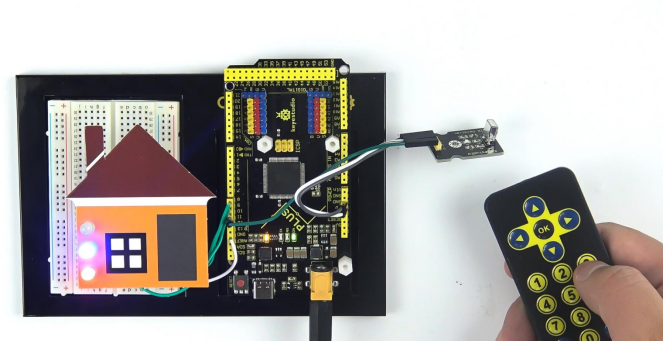

KEYESTUDIO Mega Plus STEM Starter Kit for Arduino

1.Introduction

Do you want to acquire programming knowledge? As long as you are passionate about science and dare to explore new things, this STEM starter kit must be your best choice.

KEYESTUDIO STEM Starter Kit is a programming learning kit based on Arduino. With a controller, numerous sensors, modules and electronic components, you can do many different DIY projects.

This kit also comes with 28 projects tutorials, which are entirely suitable for beginners. Each tutorial has detailed wiring diagrams and fascinating Project Codes. You can learn electronics, physics, science and programming knowledge.

2.Part List

|

|

|

|

|

|

|---|---|---|---|---|---|

Mega Plus board*1 |

LED - Blue*5 |

LED - Red*5 |

LED - Yellow*5 |

LED - Green*5 |

LED - RGB*1 |

|

|

|

|

|

|

220Ω Resistor*10 |

10KΩ Resistor*10 |

1KΩ Resistor*10 |

10KΩ Potentiometer*1 |

Buzzer (Active)*1 |

Buzzer (Passive)*1 |

|

|

|

|

|

|

Button Switch*4 |

Ball Tilt Sensor*2 |

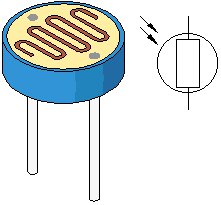

Photo Cell*3 |

Flame Sensor*1 |

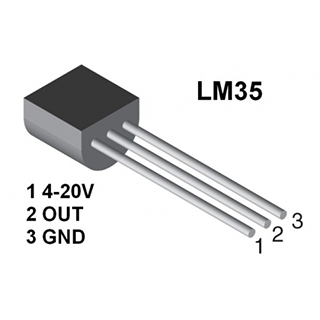

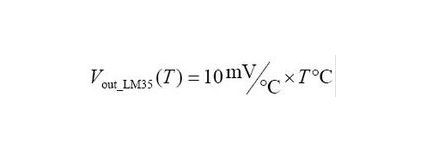

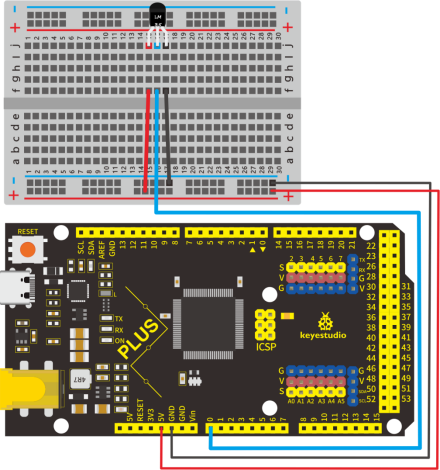

LM35 Temp Sensor*1 |

IC 74HC595N *1 |

|

|

|

|

|

|

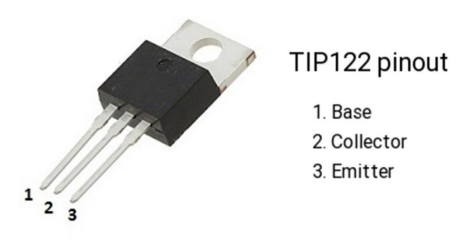

TIP122 Transistor*1 |

1 Digital Tube Display*1 |

4 Digital Tube Display*1 |

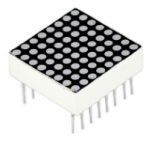

8*8 LED Matrix*1 |

1602 I2C LCD *1 |

IR Receiver*1 |

|

|

|

|

|

|

IR Remote Control*1 |

Servo Motor*1 |

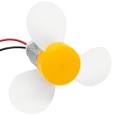

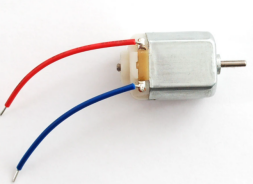

130 Motor Propeller*1 |

130 Dc Motor*1 |

Stepper Driver*1 |

Stepper Motor*1 |

|

|

|

|

|

|

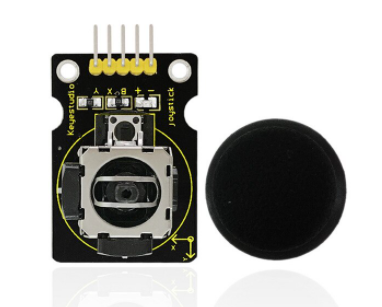

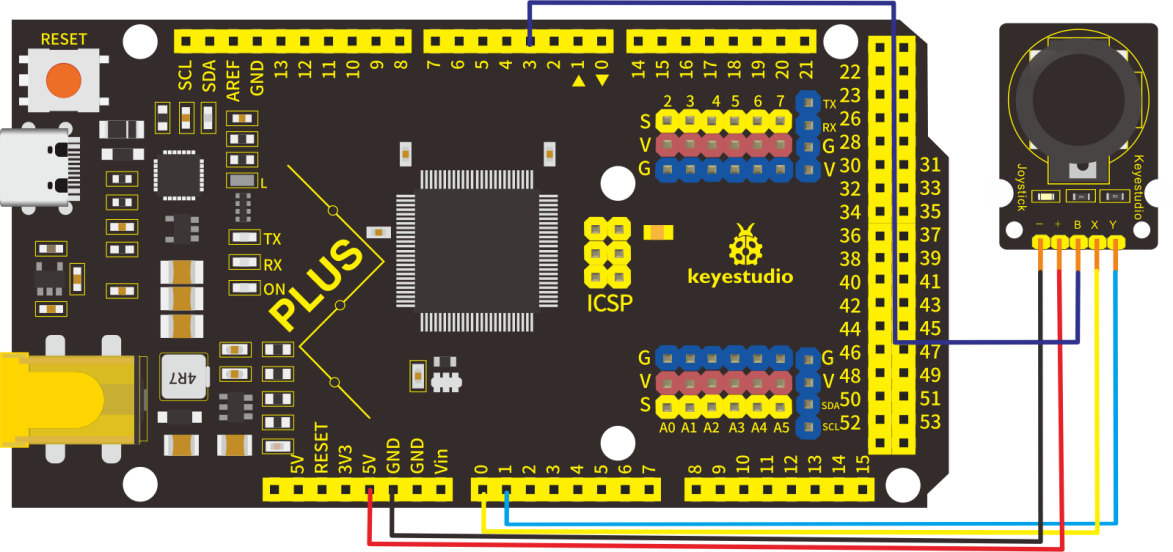

Joystick Module*1 |

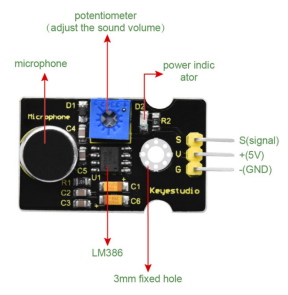

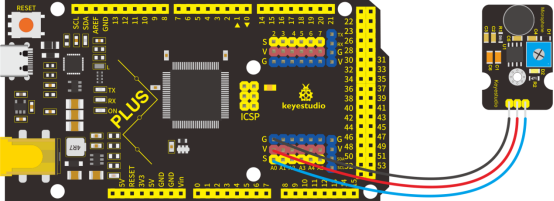

Sound Sensor*1 |

PIR Motion Sensor*1 |

HC-SR04 Ultrasonic*1 |

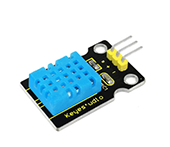

DHT11 Sensor*1 |

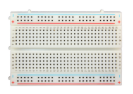

400-hole Breadboard*1 |

|

|

|

|

|

|

Arduino holder*1 |

Male to Female Dupont Wire*10 |

Female to Female Dupont Wire*10 |

Flexible jumper Wire*20 |

Preformed Jumper Wire*1 |

9v Battery Connector*1 |

|

|

|

|

|

|

Type c USB Cable*1 |

Cartoon paper |

Cartoon paper |

Cartoon paper |

Resistor card |

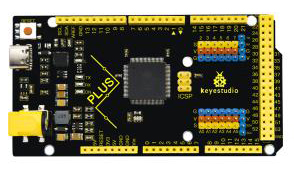

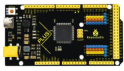

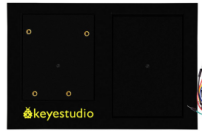

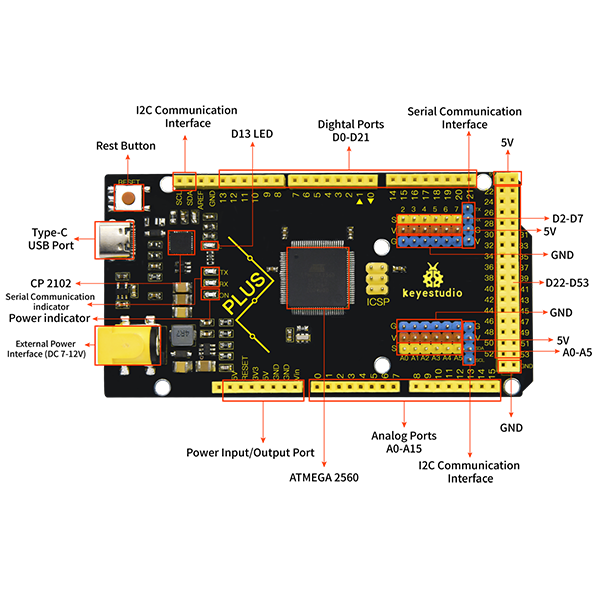

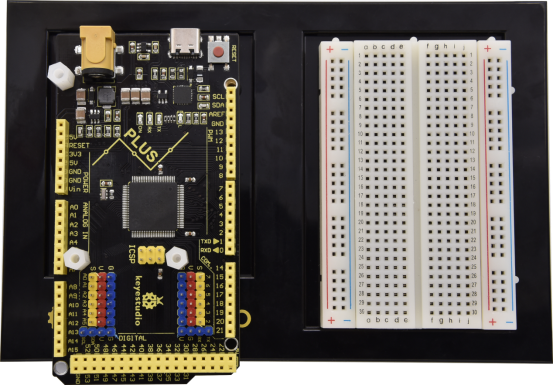

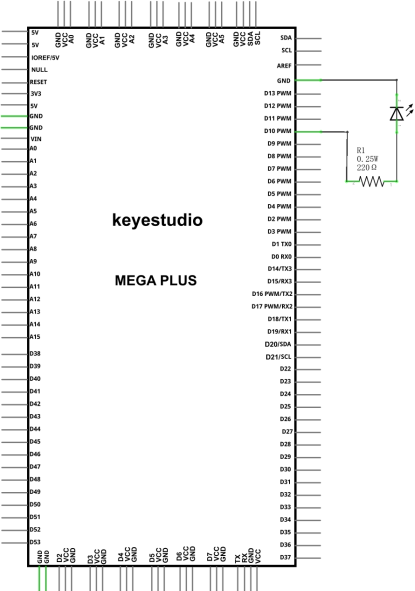

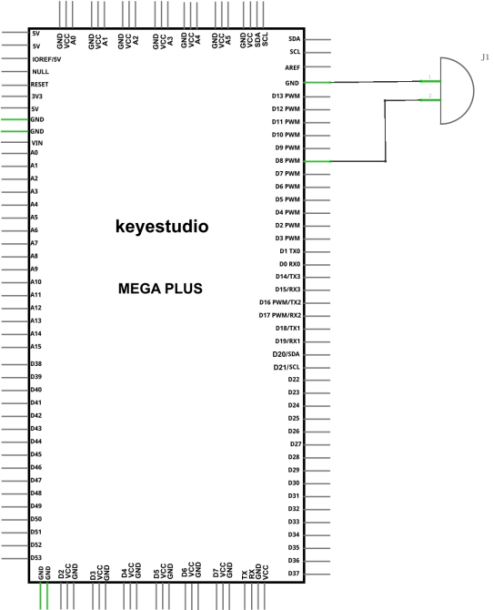

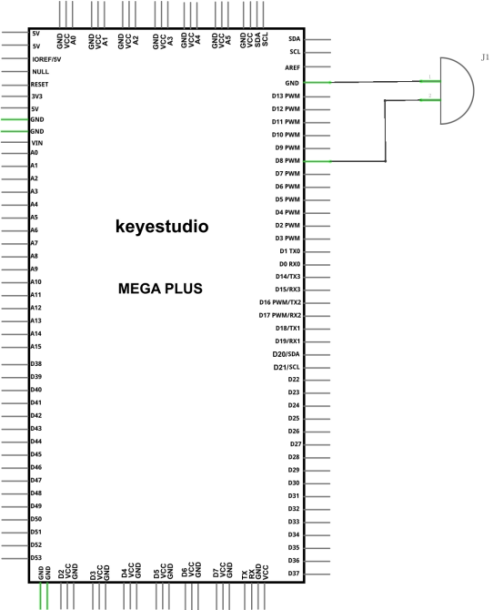

3.KEYESTUDIO Mega Plus Development Board

Before we get started with the KEYESTUDIO STEM Starter Kit, we first introduce the Mega plus development board, it is the core of all the projects.

KEYESTUIDO Mega plus board, whose processor core is ATMEGA2560-16AU, is fully compatible with ARDUINO Mega REV3.

USB to TTL chip adopts more economic and stable CP2012.

This Mega plus board consists of 54-channel digital input and output ports, of which 15 pins are served as PWM output, 16 analog inputs, 4 serial communication ports, one 16MHz crystal oscillator, 1 USB port, 1 power socket, 1 ICSP interface and 1 reset button.

Special Interfaces Description

Serial communication interface(4 channel): Serial(D0 =RX0, D1 =TX0), Serial1(D19 is RX1, D18 is TX1)

Serial2 (D17 is RX2, D16 equals to TX2), Serial3(D15 is RX3, D14 is TX3), D0 and D1 are connected to ATMEGA16U2-MU

PWM port(Pulse width modulation): D2-D13 and D44-D46

External interrupt pins:D2(interrupt 0), D3(interrupt 1), D21(interrupt 2), D20 (interrupt 3), D19(interrupt 4)and D18(interrupt 5)

SPI communication interface:D53 stands for SS, D51 is MOSI, D50 is MISO, D52 equals to SCK

IIC communication interface:D20 represents SDA, D21 is SCL

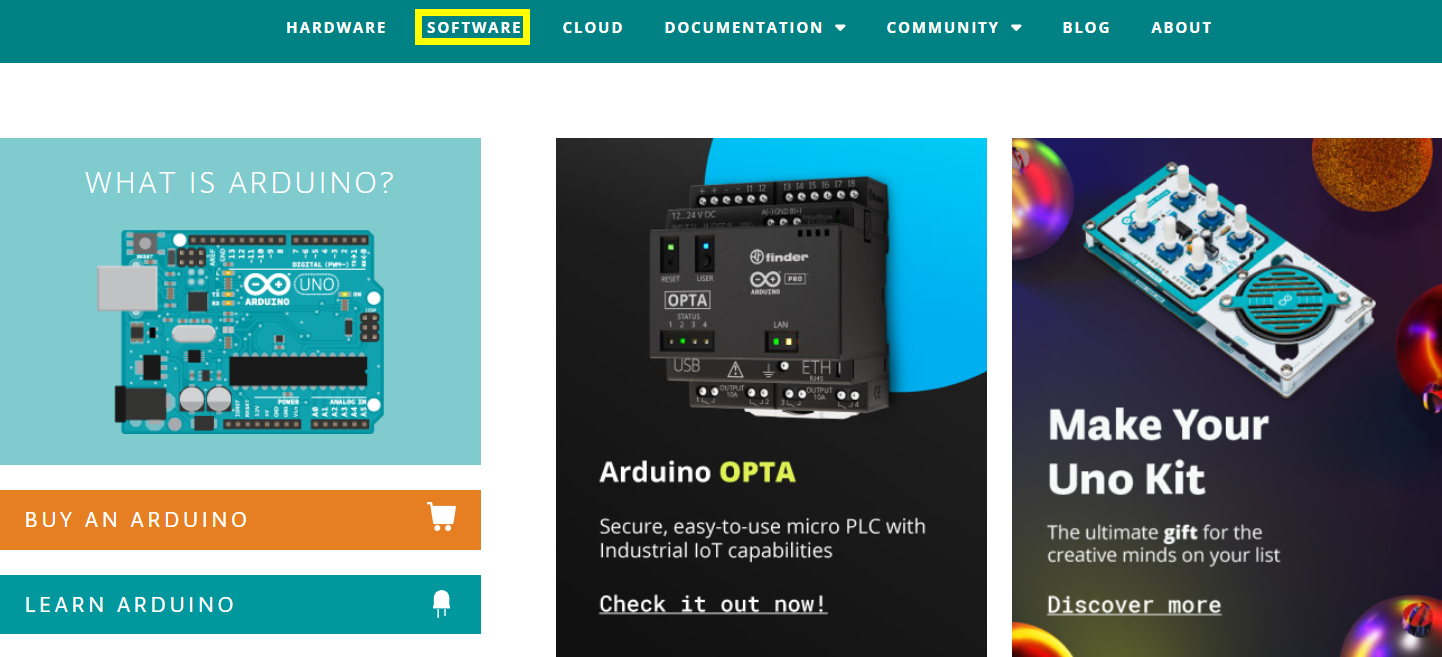

4.Install Arduino IDE and Driver

Click the link to start learning how to download software, install drivers, upload code, and install library files.

5.Project

Project 1: Hello World

1.Project Introduction

For Arduino starters, we will begin with something simple. In this project, you will only need a Mega plus development board and a USB cable to complete the “Hello World!” project. It is not only a communication test of your Arduino board and the PC, but also a primer project in the Arduino world!

2.Project Hardware

|

|

|

|

|

|---|---|---|---|---|

Mega plus Development Board*1 |

Board Holder |

400-Hole Breadboard |

USB Cable*1 |

Hello World Card*1 |

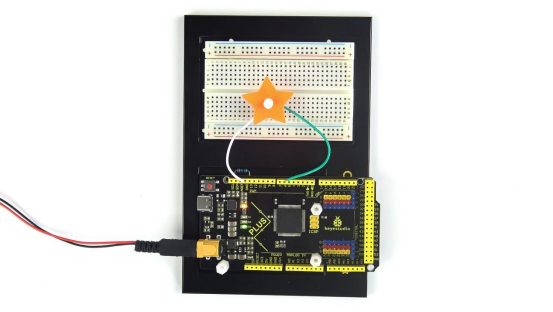

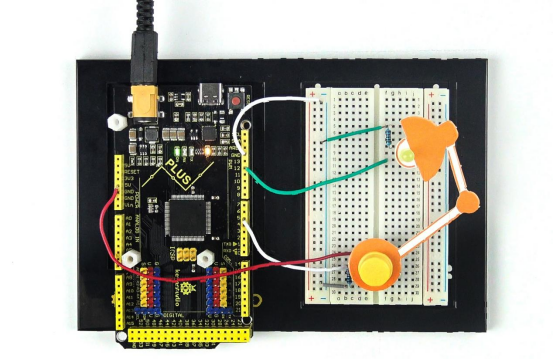

3.Assembly Project Platform

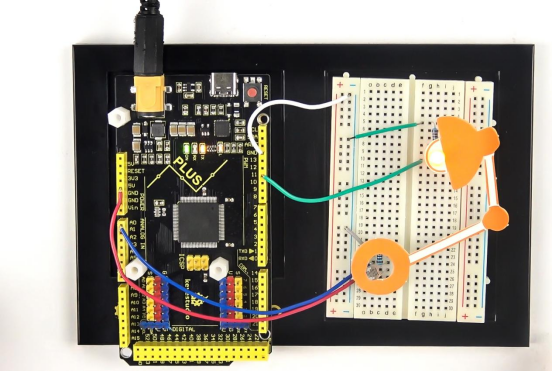

Before starting the project, we will install the Mega plus development board and 400-Hole breadboard onto the board holder.

Remove the adhesive sticker of the breadboard.

Attach the breadboard to the board holder

Use three plastic columns to fix the Mega plus development board on the board holder.

The assembly of the project platform is complete.

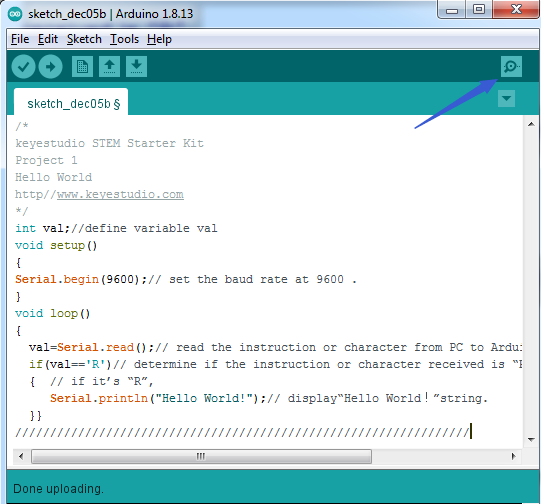

4.Project Code

A simple If () statement programming control structure will be used. Arduino uses a serial monitor for displaying information such as print statements, sensor data, and so on. This is a very powerful tool for debugging long codes. Now for your first code!

/*

keyestudio STEM Starter Kit

Project 1

Hello World

http//www.keyestudio.com

*/

int val;//define variable val

void setup()

{

Serial.begin(9600);// set the baud rate at 9600 .

}

void loop()

{

val=Serial.read();// read the instruction or character from PC to Arduino, and assign them to Val.

if(val=='R')// determine if the instruction or character received is “R”.

{ // if it’s “R”,

Serial.println("Hello World!");// display“Hello World!”string.

}

}

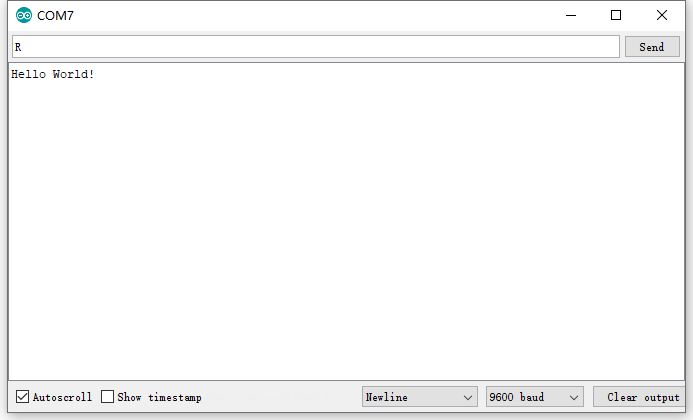

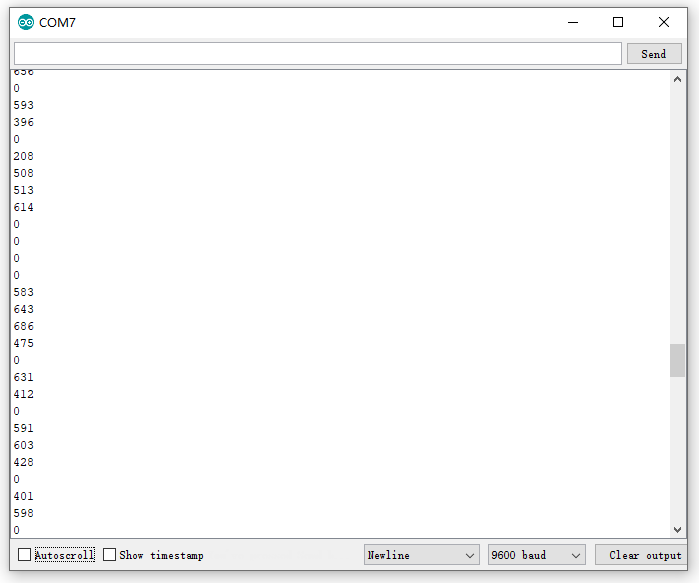

5.Project Result

Double-click  icon to enter serial monitor.

icon to enter serial monitor.

Every time you enter an “R” in the text box and click “send”, the onboard LED on the Mega plus board will flash once, and the serial monitor will display a Hello World!

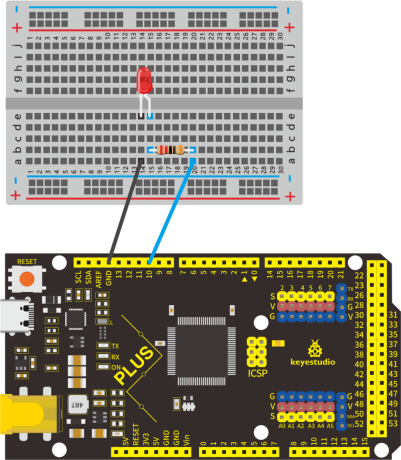

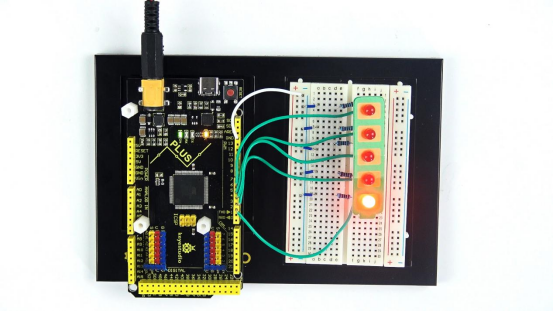

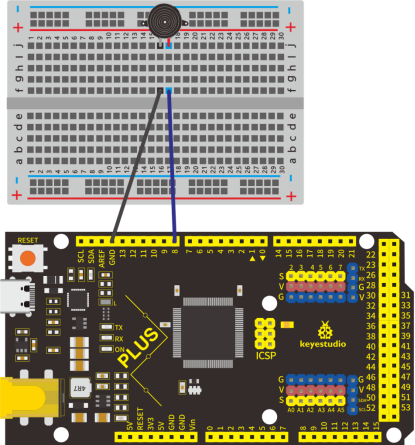

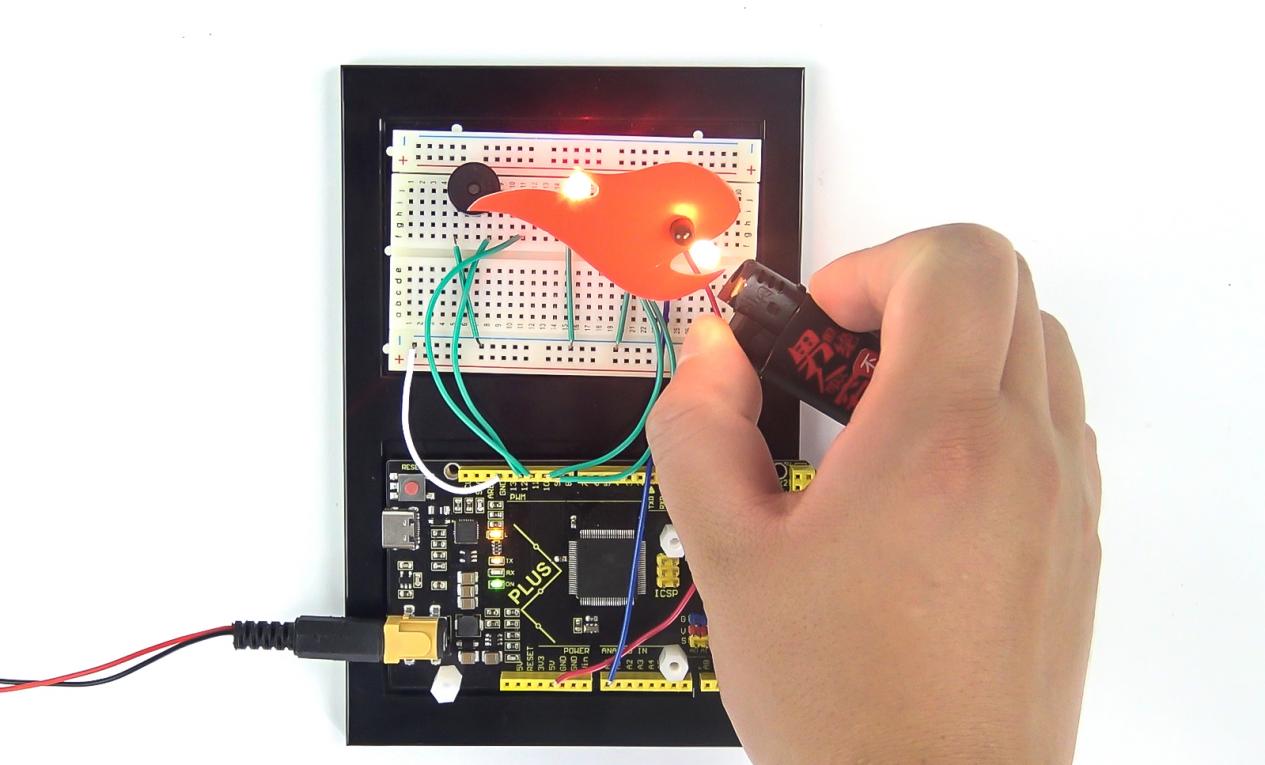

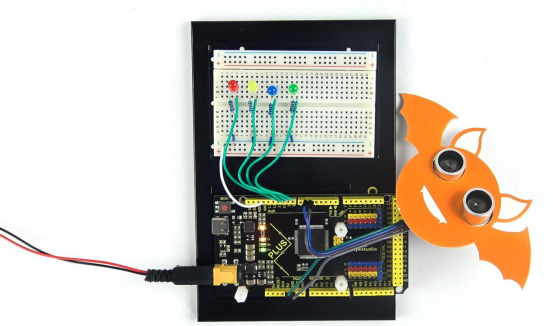

Project 2: Blinking Eyes of Dinosaur

Introduction

In this project, we will show you a dinosaur with a blinking eye.

We use the digital pin of Arduino to turn on an LED and let it blink, match with a cartoon dinosaur card we provided, the LDE will become the dinosaur’s twinkling eye.

Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Board*1 |

Plus Board holder |

400-hole Breadboard |

USB cable*1 |

|

|

|

|

Red M5 LED*1 |

220Ω Resistor*1 |

Jumper Wire*2 |

Cartoon dinosaur Card*1 |

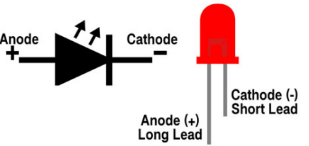

Introduction Of Electronic Components

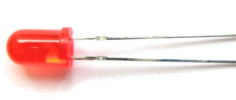

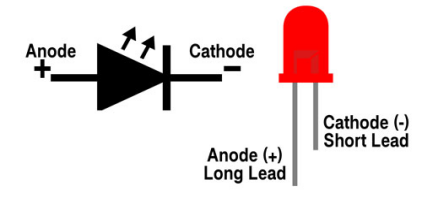

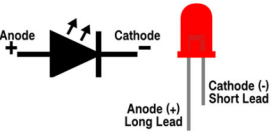

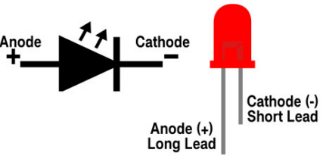

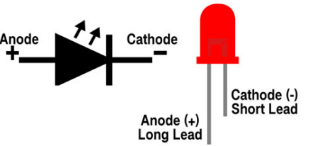

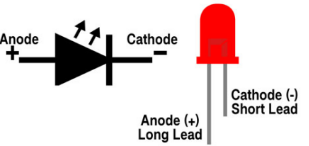

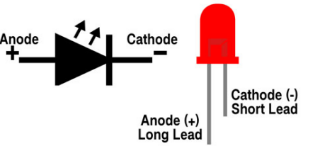

1.LED:

LED is a type of semiconductor called “Light Emitting Diode” which is an electronic device made of semiconductor materials (silicon, selenium, germanium, etc). It has positive and negative poles. The short leg is the negative pole to connect GND, and the long one is the positive pole to connect 5V.

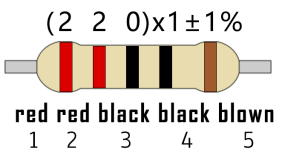

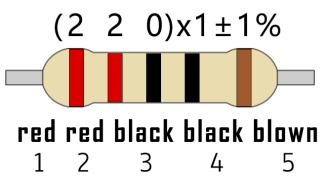

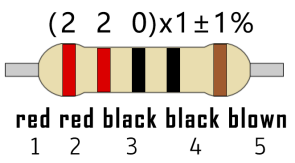

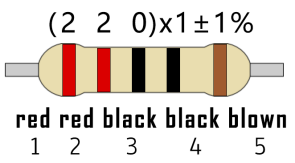

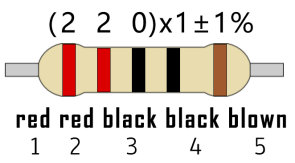

2. Five Band Resistor

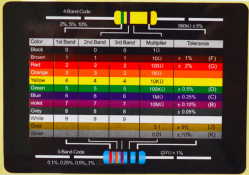

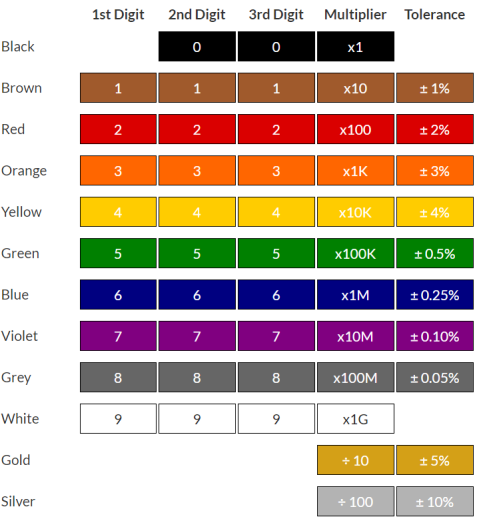

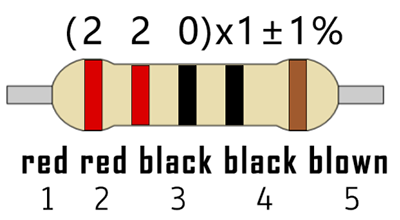

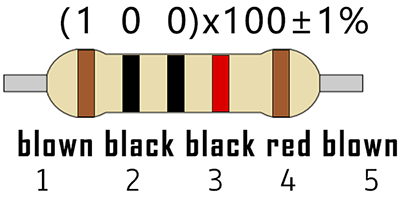

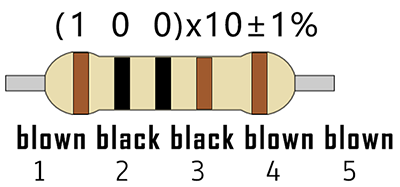

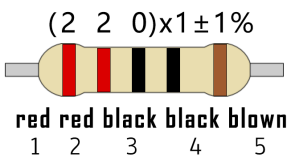

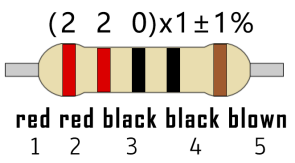

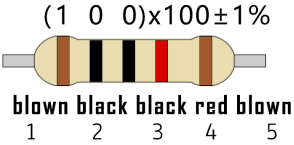

A resistor is an electronic component in the circuit, which limits and regulates the current flow. Its unit is (Ω).

-Band 1 – First significant digit.

-Band 2 – Second significant digit.

-Band 3 – Third significant digit.

-Band 4 – Multiplier.

-Band 5 – Tolerance.

In this kit, we provide three five-band resistors with different resistance values.

220Ω Resistor*10

10KΩ Resistor*10

1KΩ Resistor*10

3. Breadboard:

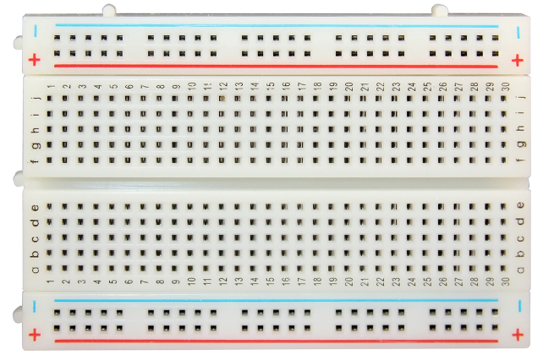

The breadboard is used to build and test circuits quickly before finalizing any circuit design. The breadboard has many holes which circuit components like ICs and resistors can be inserted into.

A typical breadboard is shown below:

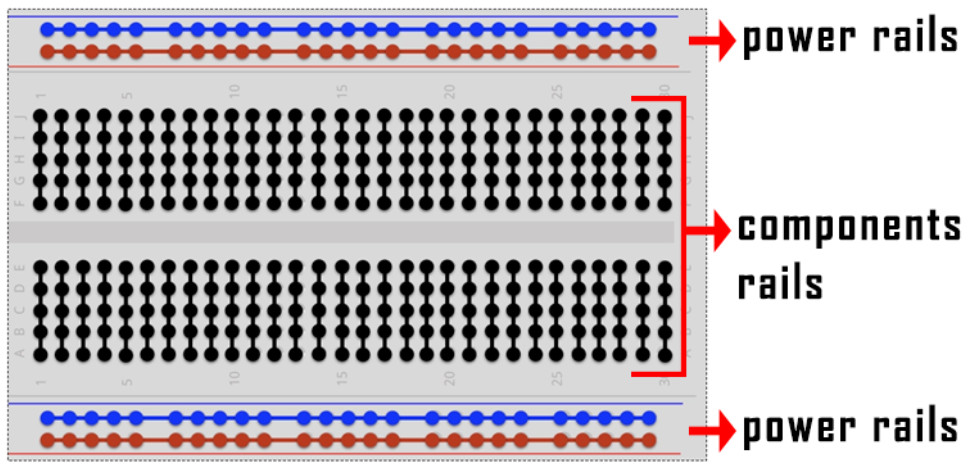

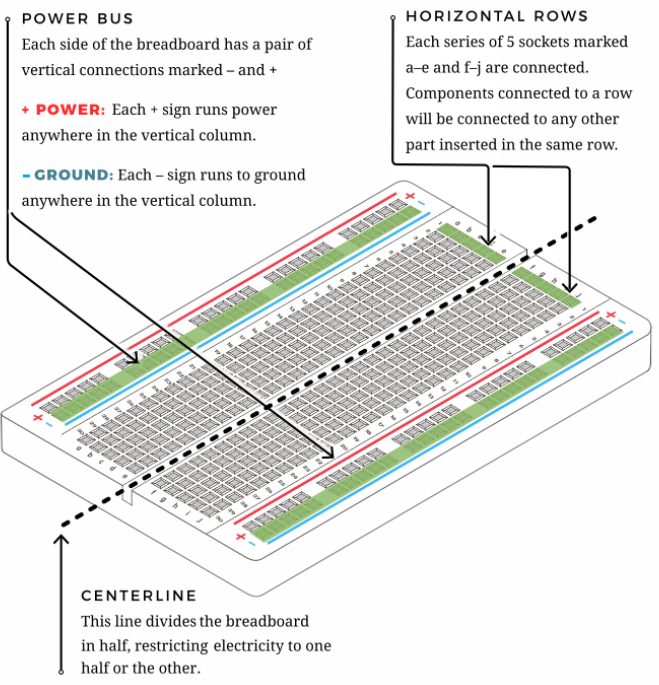

The bread board has strips of metal which run underneath the board and connect the holes on the top of the board.

The metal strips are laid out as shown below. Note that the top and bottom rows of holes are connected horizontally while the remaining holes are connected vertically.

The first two rows (top) and last two rows (bottom) of the breadboard are used for positive and for negative.

The conductive layout diagram of the breadboard is shown in the figure above.

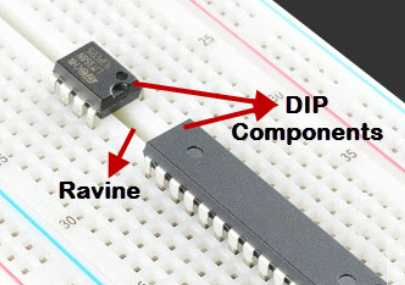

The electronics beginners may get confused while connecting the DIP (Dual In-line Packages) components such as integrated circuits, microcontrollers, chips, etc.,. The rails are isolated by ravine or crevasse, thus the rows are not connected to each other on either side. So, the DIP components can be connected as shown in the figure below.

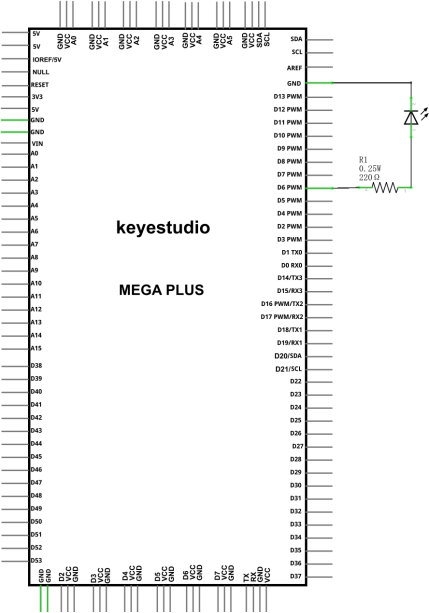

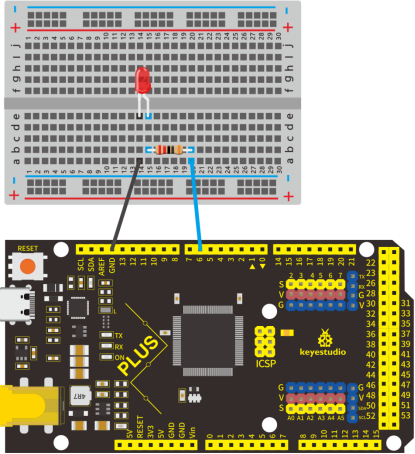

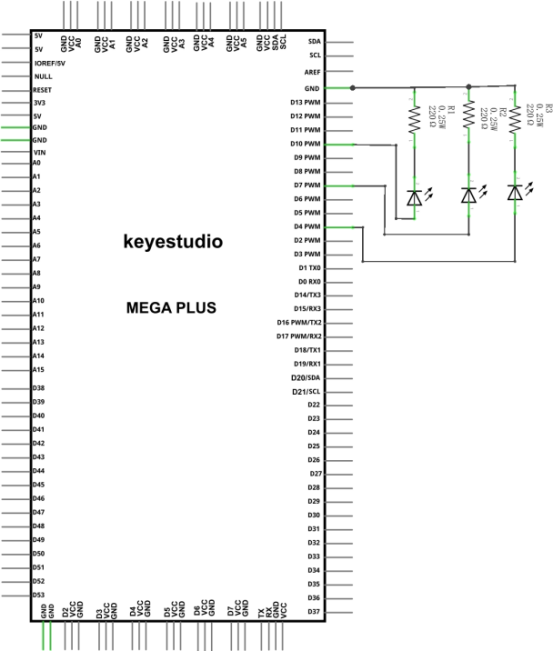

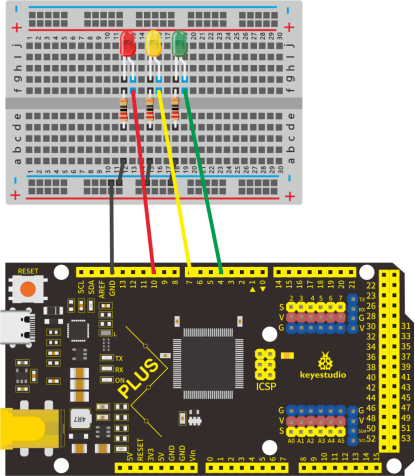

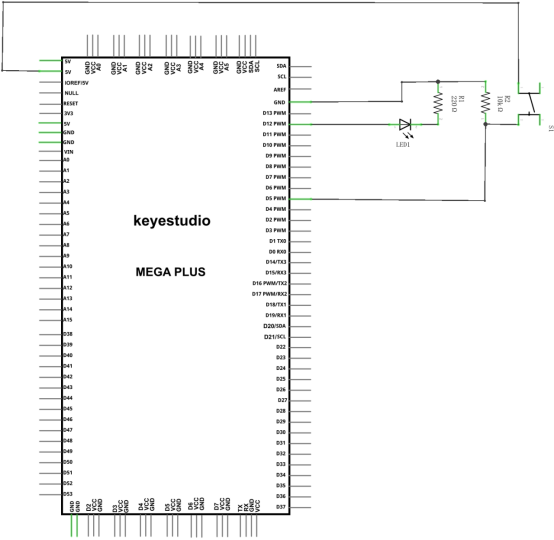

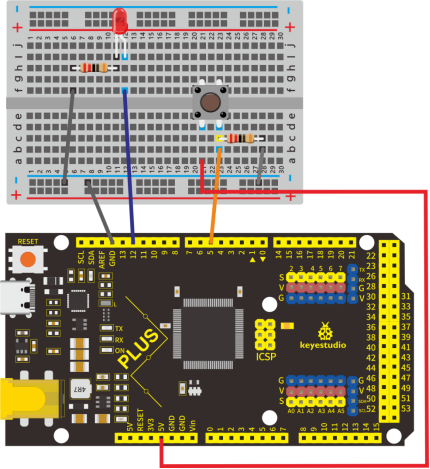

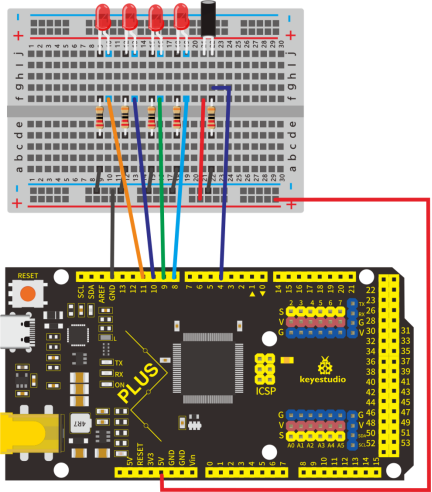

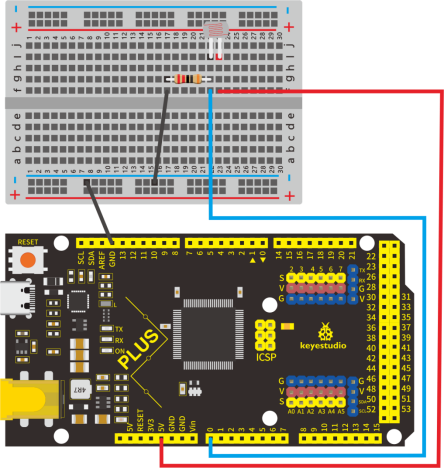

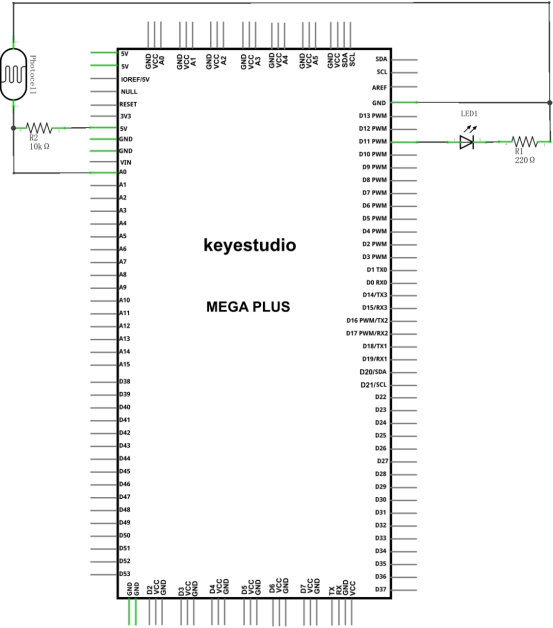

Circuit Connection

Look at the circuit schematic and wiring diagram of the project. Here we use digital pin 10 and connect an LED to a 220 ohm resistor to avoid high current damaging the LED.

Wiring Diagram

NOTE:

How to connect an LED

How to identify 5 band 220Ω Resistor

Project Code

/*

keyestudio STEM Starter Kit

Project 2

Dinosaur Blink Eyes

http//www.keyestudio.com

*/

int ledPin = 10; // define digital pin 10.

void setup()

{

pinMode(ledPin, OUTPUT);// define led pin as output.

}

void loop()

{

digitalWrite(ledPin, HIGH); // set the LED on.

delay(1000); // wait for a second.

digitalWrite(ledPin, LOW); // set the LED off.

delay(1000); // wait for a second

}

1.Open up the Arduino IDE and copy the below code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button on Arduino IDE to upload code.

Project Result

Done uploading. The LED light connected to the D10 pin of the development board turns on and off every second.

Put the dinosaur card on the LED bulb like the picture below, and you will get a cute little dinosaur that can continue to blink its eye.

Project 3: Little Star

1.Project Introduction

In this project, we will learn the PWM control of ARDUINO. PWM is the abbreviation of Pulse Width Modulation, which is a technology that encodes analog signal level into digital signal level.

Here, we use PWM to control the brightness of an LED from bright to dark gradually. Match our customized star card, you will get a flickering star.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Board*1 |

Plus Board holder |

400-hole Breadboard |

USB cable*1 |

|

|

|

|

M5 Red LED*1 |

220Ω Resistor*1 |

Jumper Wire*2 |

Cartoon Little Star Card*1 |

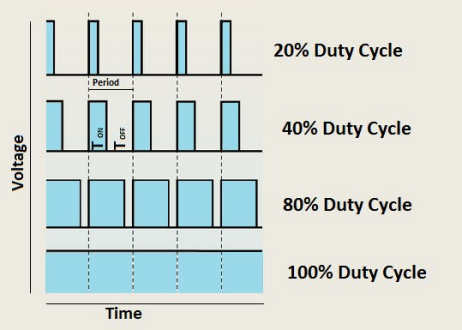

3.PWM Working Principle

PWM stands for Pulse Width Modulation and it is a technique to control LED’s brightness, speed of DC motor and servo motor.

The Arduino digital pins either produces 5V (when turned HIGH) or 0V (when turned LOW). Yet, it output a square wave signal. So if we want to dim a LED, we cannot get the voltage between 0 and 5V from the digital pin but we can change the ON and OFF time of the signal. If we will change the ON and OFF time fast enough then the brightness of the led will be changed.

Before going further, let’s discuss some terms associated with PWM.

TON (On Time): It is the time when the signal is high.

TOFF (Off Time): It is the time when the signal is low.

Period: It is the sum of on time and off time.

Duty Cycle: It is the percentage of time when the signal is high during the time of period.

So at 50% duty cycle and 1Hz frequency, the led will be high for half a second and will be low for the other half second. If we increase the frequency to 50Hz (50 times ON and OFF per second), then the led will be seen glowing at half brightness by the human eye.

Arduino and PWM

The Arduino IDE has a built in function “analogWrite()” which can be used to generate a PWM signal. The frequency of this generated signal for most pins will be about 490Hz and we can give the value from 0-255 using this function.

analogWrite(0) means a signal of 0% duty cycle.

analogWrite(127) means a signal of 50% duty cycle.

analogWrite(255) means a signal of 100% duty cycle.

On KEYESTUDIO Mega Plus board, the PWM pins are 3, 5, 6, 9, 10 and 11.

The PWM pins are labeled with ~ sign.

In this project, you are going to learn how to get the PWM output from the digital pins of Mega Plus board and control brightness of LED through code.

4.Circuit Connection

How to connect an LED

How to identify 5 band 220Ω Resistor

5.Project Code

/*

keyestudio STEM Starter Kit

Project 3

Little Star

http//www.keyestudio.com

*/

int ledPin = 6;

void setup()

{

pinMode(ledPin,OUTPUT);

}

void loop(){

for (int value = 0 ; value < 255; value=value+1){

analogWrite(ledPin, value);

delay(5);

}

for (int value = 255; value >0; value=value-1){

analogWrite(ledPin, value);

delay(5);

} }

1.Open up the Arduino IDE and copy the below code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button on Arduino IDE to upload code.

6.Project Result

Done uploading. You will see the LED lights gradually light up, and then gradually darken.

We put the card of a star on the LED, it looks like a twinkling star in the sky.

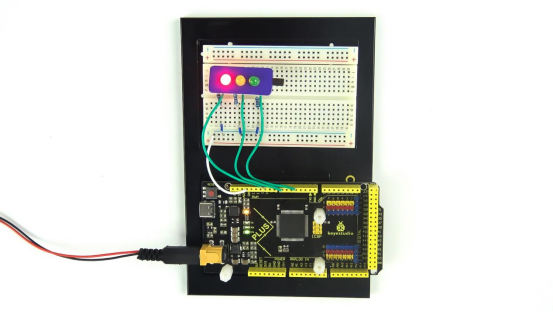

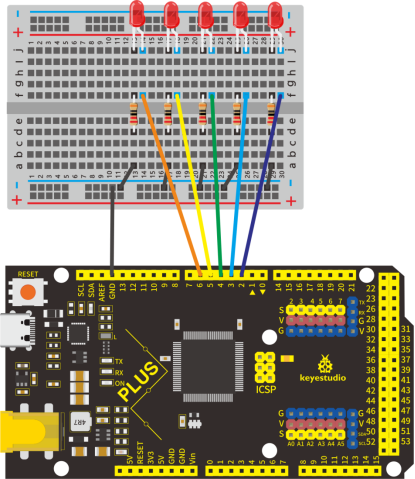

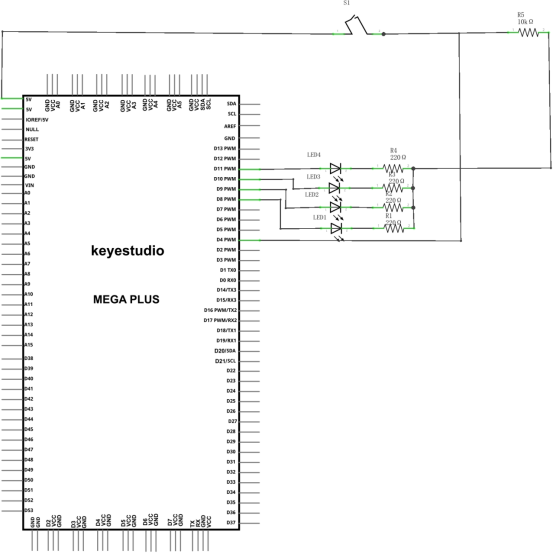

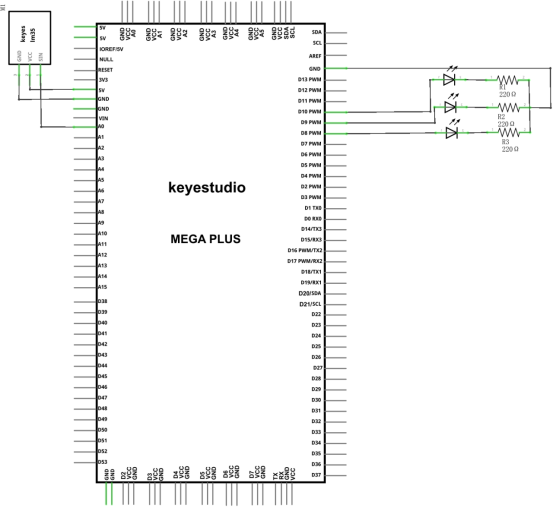

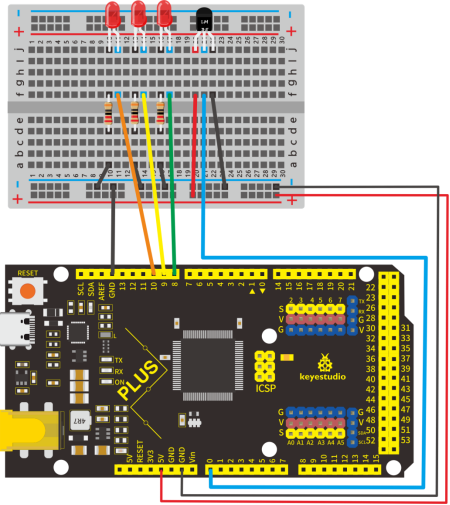

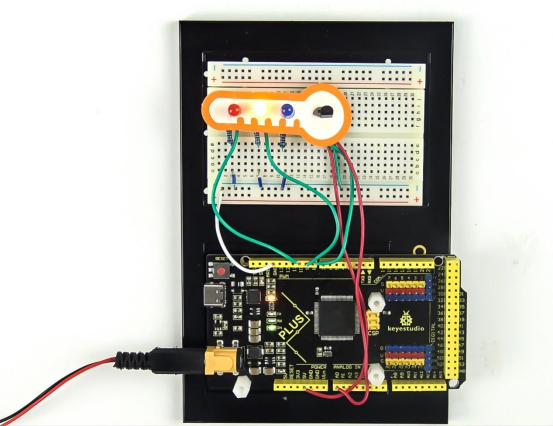

Project 4: Traffic Light

1.Project Introduction

Traffic lights are prevalent in our ordinary life. According to a certain time rule, lights operate traffic lights with three colors of red, yellow, and green. Everyone shall abide by traffic regulations, which can avoid many traffic accidents.

In this project, we will use a Mega plus development board, a traffic light card, and some LEDs(red, yellow, and green) to simulate a traffic light.

2.Project Hardware

|

|

|

|

|

|---|---|---|---|---|

Mega Plus Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

Yellow M5 LED*1 |

|

|

|

|

|

Green M5 LED*1 |

Red M5 LED*1 |

220Ω Resistor*3 |

Preformed Jumper Wire*3 Flexible jumper Wire*4 |

Traffic Light*1 |

3.Circuit Connection

NOTE:

How to connect an LED

How to identify 5 band 220Ω Resistor

4.Project Code

Since it is a simulation of traffic lights, the blinking time of each LED should be the same as those in traffic lights system.

In this program, we use Arduino delay () function to control delay time, which is much simpler than C language.

/*

keyestudio STEM Starter Kit

Project 4

traffic light

http//www.keyestudio.com

*/

int redled =10; // initialize digital pin 10.

int yellowled =7; // initialize digital pin 7.

int greenled =4; // initialize digital pin 4.

void setup()

{

pinMode(redled, OUTPUT);// set the pin with red LED as “output”

pinMode(yellowled, OUTPUT); // set the pin with yellow LED as “output”

pinMode(greenled, OUTPUT); // set the pin with blue LED as “output”

}

void loop()

{

digitalWrite(greenled, HIGH);//// turn on green LED

delay(5000);// wait 5 seconds

digitalWrite(greenled, LOW); // turn off green LED

for(int i=0;i<3;i++)// blinks for 3 times

{

delay(500);// wait 0.5 second

digitalWrite(yellowled, HIGH);// turn on yellow LED

delay(500);// wait 0.5 second

digitalWrite(yellowled, LOW);// turn off yellow LED

}

delay(500);// wait 0.5 second

digitalWrite(redled, HIGH);// turn on red LED

delay(5000);// wait 5 second

digitalWrite(redled, LOW);// turn off red LED

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button on Arduino IDE to upload code.

5.Project Result

Done uploading. Put the traffic light card on top of the three LEDs, and you have successfully made a traffic light.

First, the green light will be on for 5 seconds, and then off.

Second, the yellow light will blink for 3 times, and then off.

Third, the red light will be on for 5 seconds, and then off.

Continue to run the above 1-3 steps until you cut off the power to the Mega plus development board.

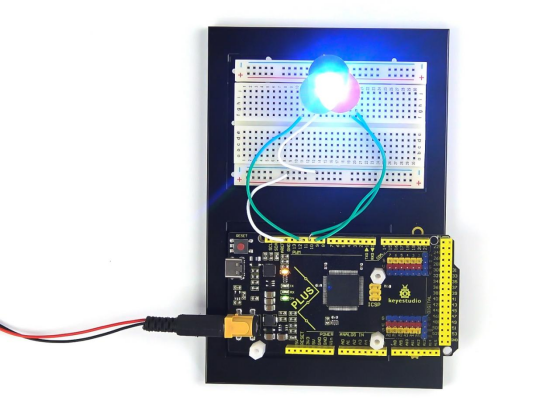

Project 5: RGB LED

1.Project Introduction

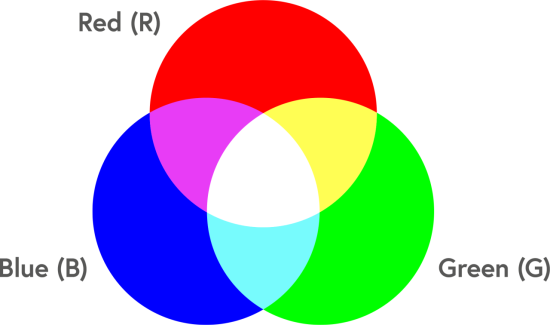

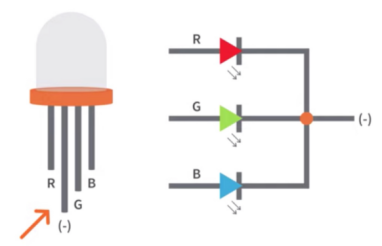

The RGB led, consisting of three colors(red, green and blue), can emit different colors by mixing this 3 basic colors.

In this project, we will introduce you RGB LED and show you how to use the Mega plus development board.

We also provide a RGB color card for you to understand it easier. Even though the RGB LED are extremely basic, it’s a great way to introduce yourself or others to the basics of electronics and coding.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

RGB LED * 1 |

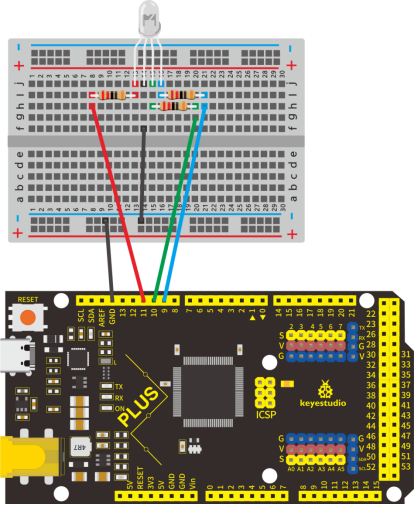

220Ω Resistor*3 |

Preformed Jumper Wire*2 Flexible jumper Wire*4 |

RGB color Card*1 |

3. Little Knowledge

The monitors mostly comply with the RGB color standard, and all the colors on the computer screen are composed of the three colors of red, green and blue mixed in different proportions.

This RGB LED has 4 pins, one for each color (Red, Green, Blue) and a common cathode. To change brightness of RGB led, we can use the PWM pins of Arduino. The PWM pins will give signal with different duty cycles to the RGB led to obtain different colors.

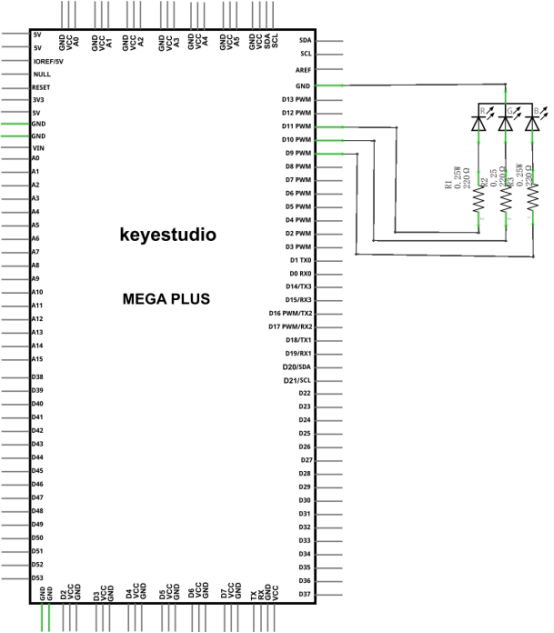

4.Circuit Connection

NOTE:

The longest pin (common cathode) of RGB LED is connected to GND.

How to identify 5 band 220Ω Resistor

5.Project Code

/*

keyestudio STEM Starter Kit

Project 5

Color Secret

http//www.keyestudio.com

*/

int redpin = 11; //select the pin for the red LED

int bluepin =9; // select the pin for the blue LED

int greenpin =10;// select the pin for the green LED

int val;

void setup() {

pinMode(redpin, OUTPUT);

pinMode(bluepin, OUTPUT);

pinMode(greenpin, OUTPUT);

Serial.begin(9600);

}

void loop()

{

for(val=255; val>0; val--)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

for(val=0; val<255; val++)

{

analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

Serial.println(val, DEC);

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Done uploading! Wait for a few seconds, you can see a colorful LED. You can also put the RGB card we provide on top of it.

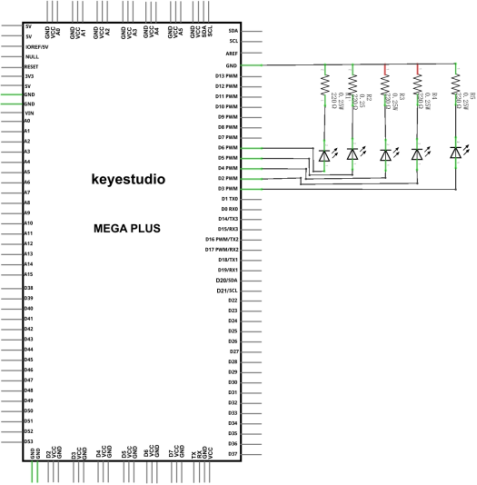

Project 6: Battery Billboard

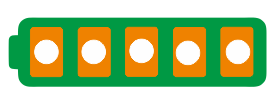

1.Project Introduction

We can see many billboards composed of different colour LEDs in daily life. They are constantly changing their light to attract customers’ attention.

In this project, we will use 5 LEDs and a battery paper card to make an advertising panel about the battery. The sparkling light string makes it easy for customers to notice your battery if you are a battery salesperson.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Red M5 LED*5 |

220Ω Resistor*5 |

Preformed Jumper Wire*5 Flexible jumper Wire*6 |

battery billboard Card*1 |

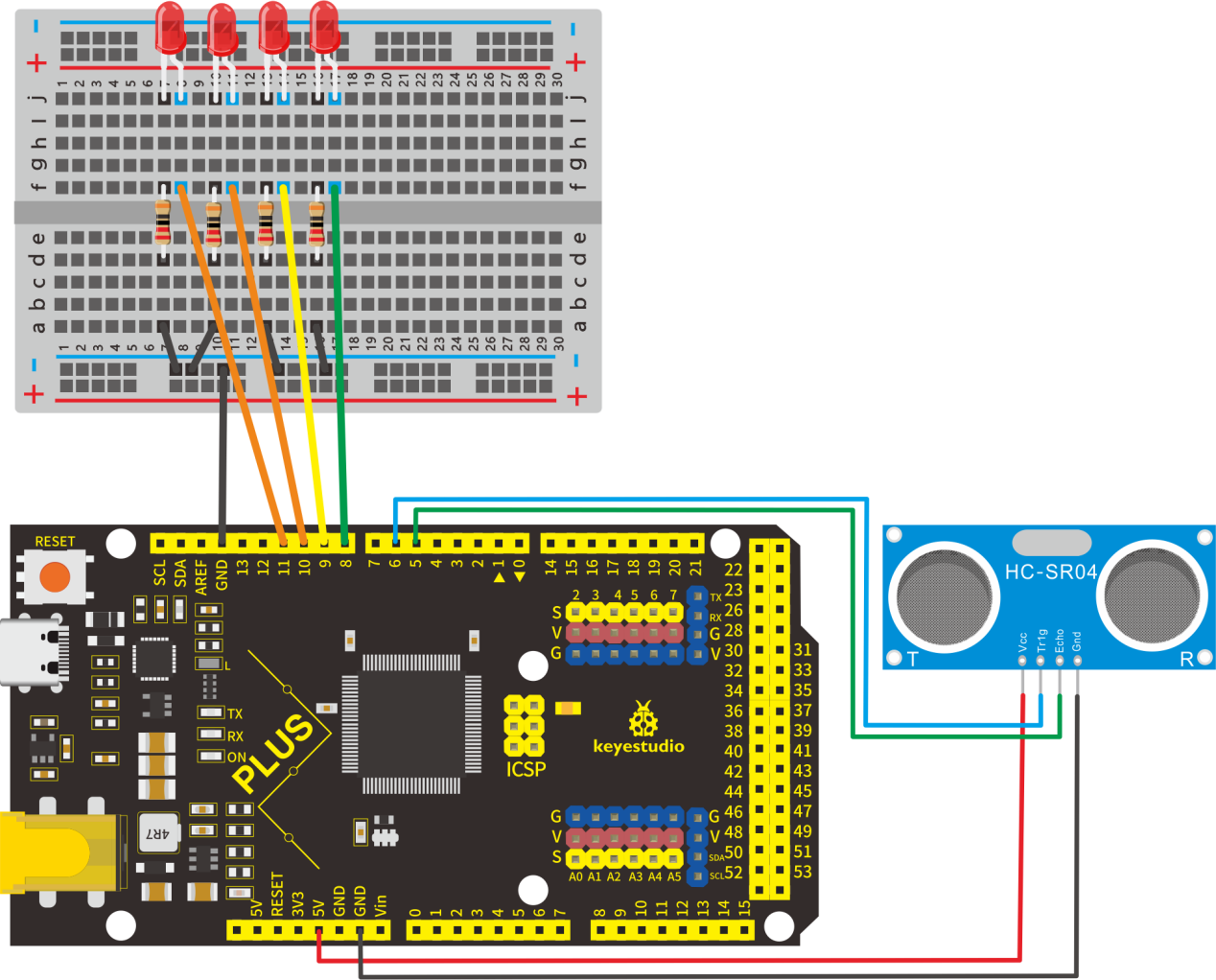

3.Circuit Connection

NOTE:

How to connect an LED

How to identify 5 band 220Ω Resistor

4.Project Code

/*

keyestudio STEM Starter Kit

Project 6

Advertising running lights

http//www.keyestudio.com

*/

int BASE = 2 ;// the I/O pin for the first LED

int NUM = 5; // number of LEDs

void setup()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

pinMode(i, OUTPUT); // set I/O pins as output

}

}

void loop()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, LOW); // set I/O pins as “low”, turn off LEDs one by one.

delay(200); // delay

}

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, HIGH); // set I/O pins as “high”, turn on LEDs one by one

delay(200); // delay

}

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

5.Project Result

Done uploading!The 5 LEDs connected to the D2-D6 pins of the development board will gradually light up and then gradually turn off, just like a battery being charged.

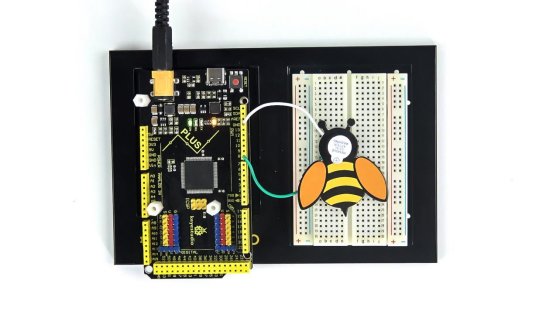

Project 7: Little Bee

1.Project Introduction

The active buzzer is a sounding component. it is widely used as a sound-making element on the computer, printer, alarm, electronic toy, telephone, timer and more. It has an inner vibration source. Simply connect it with 5V power supply, it can buzz continuously.

In this project, we will use an active buzzer and a cartoon bee card to make a cute bee that can tweet.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Active buzzer*1 |

Jumper Wire*2 |

Cartoon Small Bee Card*1 |

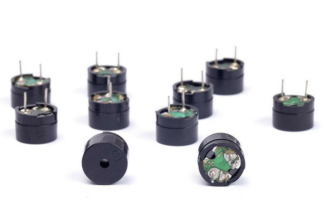

3. Little Knowledge

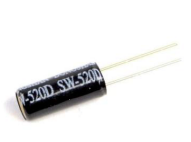

The active buzzer inside has a simple oscillator circuit which can convert constant direct current into a certain frequency pulse signal. Once active buzzer receives a high level, it will produce an audible beep.

Passive buzzer is an integrated electronic buzzer without vibration source inside. It must be driven by 2K-5K square wave instead of direct current signals.

The appearance of the two buzzers is very similar, but the one with a green circuit board is a passive buzzer, while the other enclosed with a black tape is an active one. Passive buzzers don’t differentiate positive while active polarity active buzzers do.

As shown below:

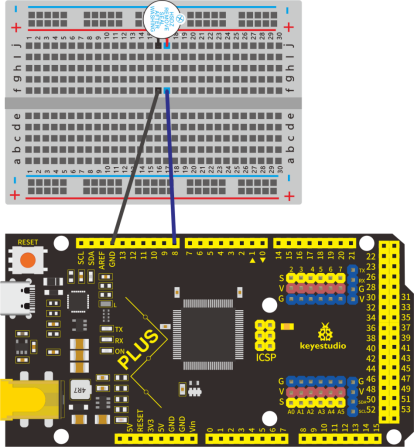

4.Circuit Connection

NOTE: The positive pole of the active buzzer is connected to pin 8 (“+”/long pin), and the negative pole is connected to GND

5.Project Code

/*

keyestudio STEM Starter Kit

Project 7

Little bee

http//www.keyestudio.com

*/

int buzzerPin = 8;

void setup ()

{

pinMode (buzzerPin, OUTPUT);

}

void loop ()

{

digitalWrite (buzzerPin, HIGH);

delay (500);

digitalWrite (buzzerPin, LOW);

delay (500);

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Done uploading!Put the cartoon paper of the little bee on it, You will get a little bee that can tweet.

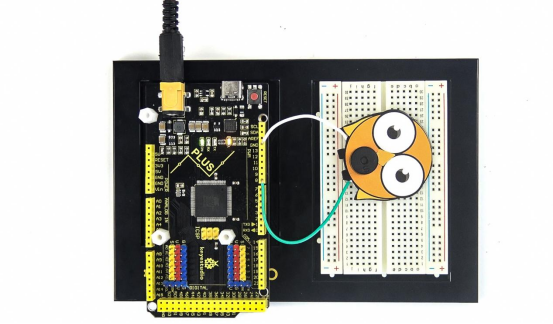

Project 8: Bird That Can Sing

1.Project Introduction

In the previous project, we studied the active buzzer, which can only emit one sound and may make you feel monotonous.

This project will learn another buzzer, passive buzzer. Unlike an active buzzer, a passive buzzer can emit sounds of different frequencies.

In this project, you will get a bird that can sing which is made by a cartoon bird card and the passive buzzer we provide.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Passive Buzzer*1 |

Jumper Wire*2 |

Cartoon Small Bird Card*1 |

3. Little knowledge

Passive buzzer is an integrated electronic buzzer without vibration source inside. It must be driven by 2K-5K square wave instead of direct current signals. The appearance of the two buzzers is very similar, but the one with a green circuit board is a passive buzzer, while the other enclosed with a black tape is an active one. Passive buzzers don’t differentiate positive while active polarity active buzzers do.

4.Circuit Connection

5.Project Code

/*

keyestudio STEM Starter Kit

Project 8

Singing bird

http//www.keyestudio.com

*/

#define NOTE_B0 31

#define NOTE_C1 33

#define NOTE_CS1 35

#define NOTE_D1 37

#define NOTE_DS1 39

#define NOTE_E1 41

#define NOTE_F1 44

#define NOTE_FS1 46

#define NOTE_G1 49

#define NOTE_GS1 52

#define NOTE_A1 55

#define NOTE_AS1 58

#define NOTE_B1 62

#define NOTE_C2 65

#define NOTE_CS2 69

#define NOTE_D2 73

#define NOTE_DS2 78

#define NOTE_E2 82

#define NOTE_F2 87

#define NOTE_FS2 93

#define NOTE_G2 98

#define NOTE_GS2 104

#define NOTE_A2 110

#define NOTE_AS2 117

#define NOTE_B2 123

#define NOTE_C3 131

#define NOTE_CS3 139

#define NOTE_D3 147

#define NOTE_DS3 156

#define NOTE_E3 165

#define NOTE_F3 175

#define NOTE_FS3 185

#define NOTE_G3 196

#define NOTE_GS3 208

#define NOTE_A3 220

#define NOTE_AS3 233

#define NOTE_B3 247

#define NOTE_C4 262

#define NOTE_CS4 277

#define NOTE_D4 294

#define NOTE_DS4 311

#define NOTE_E4 330

#define NOTE_F4 349

#define NOTE_FS4 370

#define NOTE_G4 392

#define NOTE_GS4 415

#define NOTE_A4 440

#define NOTE_AS4 466

#define NOTE_B4 494

#define NOTE_C5 523

#define NOTE_CS5 554

#define NOTE_D5 587

#define NOTE_DS5 622

#define NOTE_E5 659

#define NOTE_F5 698

#define NOTE_FS5 740

#define NOTE_G5 784

#define NOTE_GS5 831

#define NOTE_A5 880

#define NOTE_AS5 932

#define NOTE_B5 988

#define NOTE_C6 1047

#define NOTE_CS6 1109

#define NOTE_D6 1175

#define NOTE_DS6 1245

#define NOTE_E6 1319

#define NOTE_F6 1397

#define NOTE_FS6 1480

#define NOTE_G6 1568

#define NOTE_GS6 1661

#define NOTE_A6 1760

#define NOTE_AS6 1865

#define NOTE_B6 1976

#define NOTE_C7 2093

#define NOTE_CS7 2217

#define NOTE_D7 2349

#define NOTE_DS7 2489

#define NOTE_E7 2637

#define NOTE_F7 2794

#define NOTE_FS7 2960

#define NOTE_G7 3136

#define NOTE_GS7 3322

#define NOTE_A7 3520

#define NOTE_AS7 3729

#define NOTE_B7 3951

#define NOTE_C8 4186

#define NOTE_CS8 4435

#define NOTE_D8 4699

#define NOTE_DS8 4978

#define REST 0

int tempo=114; // change this to make the song slower or faster

int buzzer = 8;// change this to whichever pin you want to use

// notes of the moledy followed by the duration.

// a 4 means a quarter note, 8 an eighteenth , 16 sixteenth, so on

// !!negative numbers are used to represent dotted notes,

// so -4 means a dotted quarter note, that is, a quarter Plus an eighteenth!!

int melody[] = {

NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//1

NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4,

NOTE_E4,-4, NOTE_D4,8, NOTE_D4,2,

NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//4

NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4,

NOTE_D4,-4, NOTE_C4,8, NOTE_C4,2,

NOTE_D4,4, NOTE_D4,4, NOTE_E4,4, NOTE_C4,4,//8

NOTE_D4,4, NOTE_E4,8, NOTE_F4,8, NOTE_E4,4, NOTE_C4,4,

NOTE_D4,4, NOTE_E4,8, NOTE_F4,8, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_D4,4, NOTE_G3,2,

NOTE_E4,4, NOTE_E4,4, NOTE_F4,4, NOTE_G4,4,//12

NOTE_G4,4, NOTE_F4,4, NOTE_E4,4, NOTE_D4,4,

NOTE_C4,4, NOTE_C4,4, NOTE_D4,4, NOTE_E4,4,

NOTE_D4,-4, NOTE_C4,8, NOTE_C4,2

};

// sizeof gives the number of bytes, each int value is composed of two bytes (16 bits)

// there are two values per note (pitch and duration), so for each note there are four bytes

int notes=sizeof(melody)/sizeof(melody[0])/2;

// this calculates the duration of a whole note in ms (60s/tempo)*4 beats

int wholenote = (60000 * 4) / tempo;

int divider = 0, noteDuration = 0;

void setup() {

// iterate over the notes of the melody.

// Remember, the array is twice the number of notes (notes + durations)

for (int thisNote = 0; thisNote < notes * 2; thisNote = thisNote + 2) {

// calculates the duration of each note

divider = melody[thisNote + 1];

if (divider > 0) {

noteDuration = (wholenote) / divider; // regular note, just proceed

} else if (divider < 0) {

// dotted notes are represented with negative durations!!

noteDuration = (wholenote) / abs(divider);

noteDuration *= 1.5; // increases the duration in half for dotted notes

}

// we only play the note for 90% of the duration, leaving 10% as a pause

tone(buzzer, melody[thisNote], noteDuration*0.9);

// Wait for the specief duration before playing the next note.

delay(noteDuration);

noTone(buzzer); // stop the waveform generation before the next note.

}

}

void loop() {

// if you want to repeat the song forever, paste the setup code here .

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Upload the project code to the Mega plus development board.

Put the cartoon paper of the bird on it, and can get a bird that can sing a nice song.

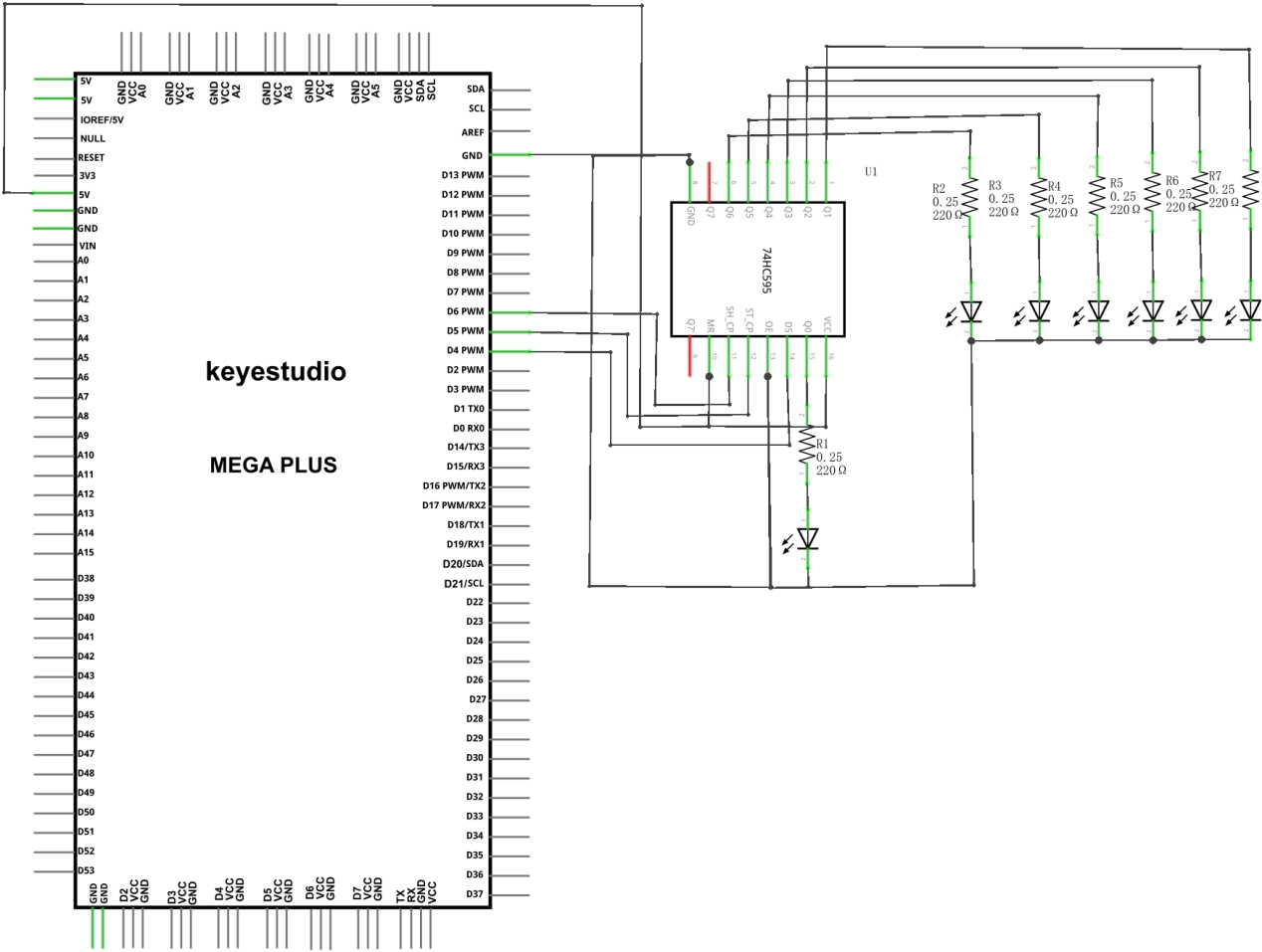

Project 9: Laser Bar

1.Project Introduction

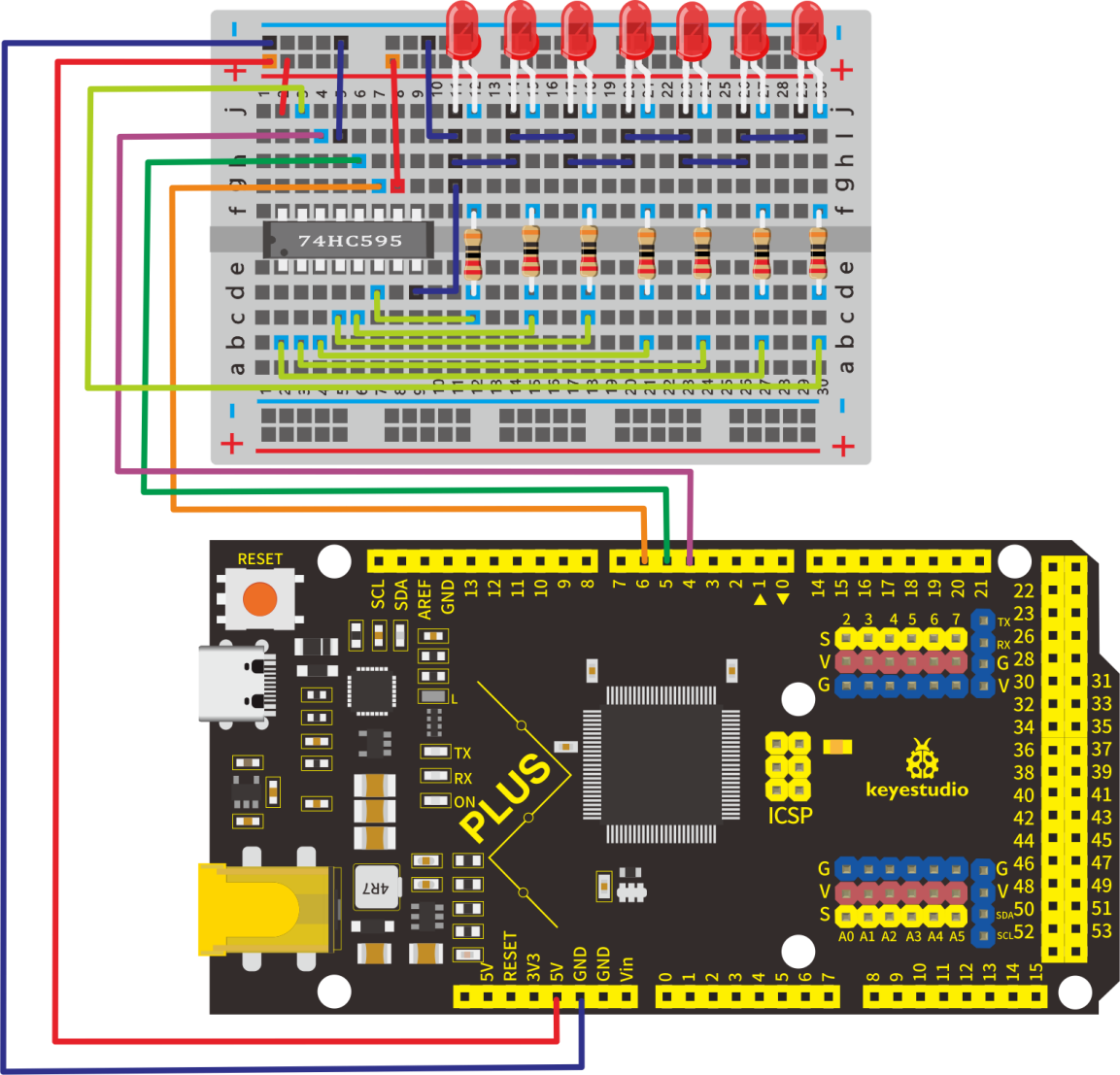

In the previous project, we have learned how to light up a LED. There are only 22 IO ports on the Mega plus development board. How can we light up a large number of LEDs? At sometime may run out of pins on your Arduino board and need to extend it with shift registers.

You can use the 74HC595N to control 8 outputs at a time while only taking up a few pins on your microcontroller. You can also link multiple registers together to extend your output even more.

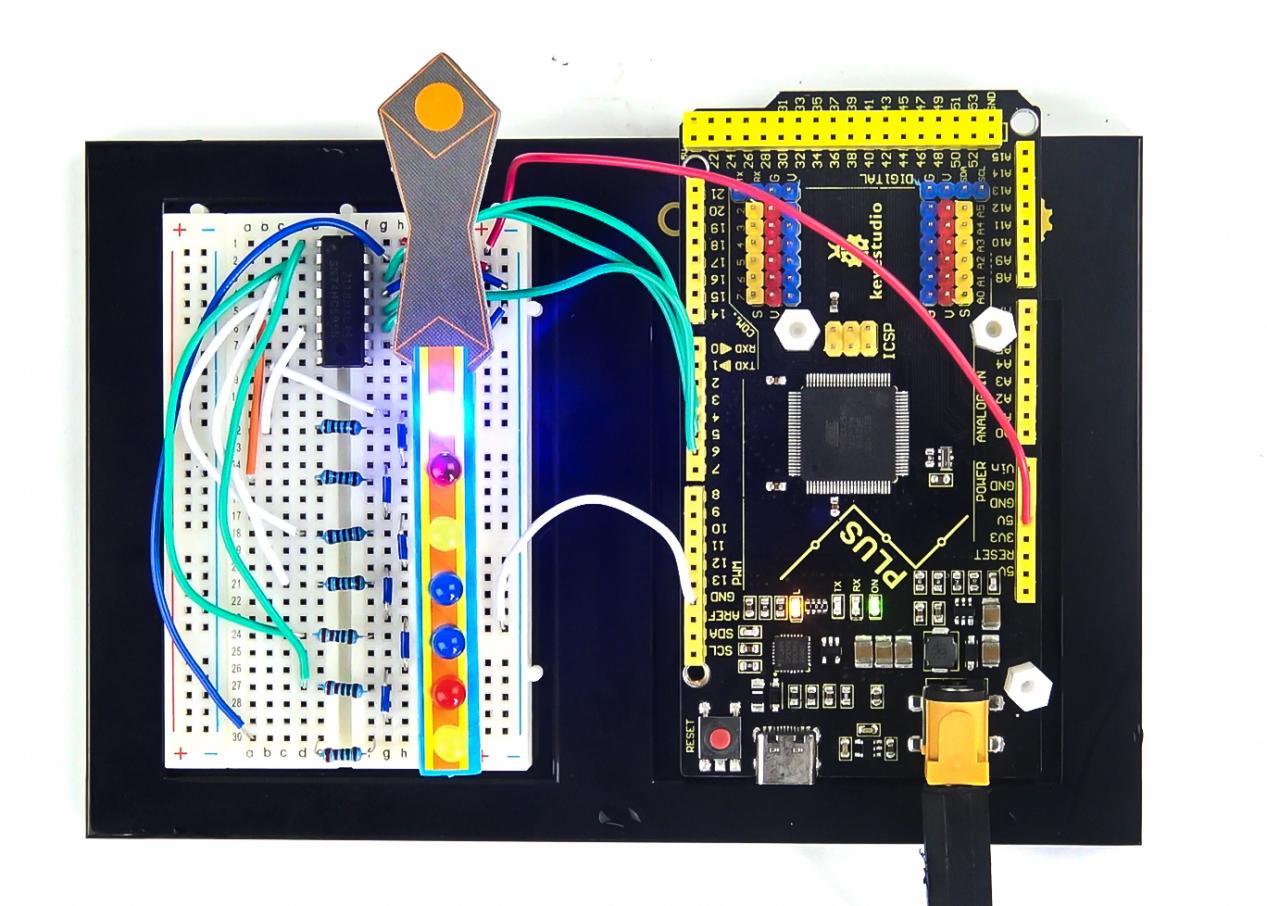

In this project, we will use 4 Red M5 LEDs, 3 Green M5 LEDs and the laser stick card we provide to make an exciting laser stick model.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

74HC595 chip*1 |

Red M5 LED *4 |

Green M5 LED *3 |

220Ω Resistor*7 |

|

|

||

Preformed/Flexible Jumper Wire*20+ |

Laser Stick Paper Card*1 |

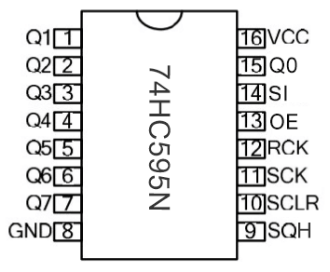

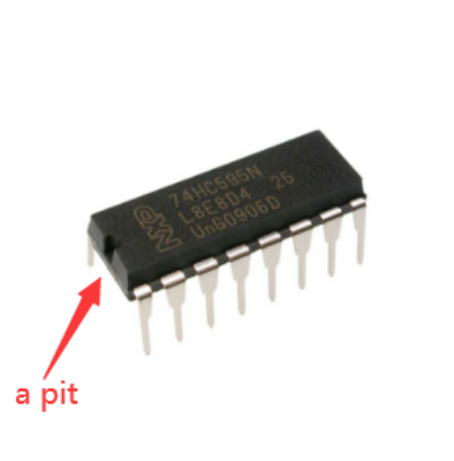

3. 74HC595 Chip Pins Description:

Pins No. |

Name |

Function |

|---|---|---|

1-7, 15 |

Q0-Q7 |

Parallel Output |

8 |

GND |

GND |

9 |

MR |

Serial Output |

10 |

Master Reserve , connect 5V |

|

11 |

SH_CP |

Shift Register Clock Output |

12 |

ST_CP |

Storage Register Clock Input |

13 |

OE |

Output Enable (active LOW) |

14 |

DS |

Serial data input |

16 |

Vcc |

5V working voltage |

VCC and GND are used to supply power for chip, the working voltage is 5V.

Q0~Q7:This eight pins are output pins.

DS pin is serial input pin, we need to write data into this pin by bit.

STCP is a latch pin. The data can be copied to latch and output in parallel after 8-digit data of latch is all transmitted.

SHCP is a clock pin. The data can be written into storage register.

OE is an output enable pin, which is used to make sure if the data of latch is input into Q0-Q7 pins. When in low level, high level is not output. In this experiment, we directly connect to GND to keep low level output data.

MR is a pin to initialize the pin of storage register. Initialize the internal storage register when low level. In this experiment, we connect to VCC to keep high level.

Q7S pin is a serial output pin, which is specially used for chip cascade.

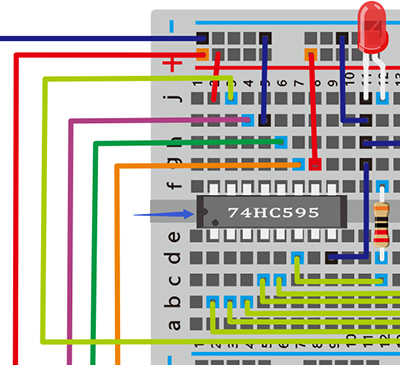

4.Circuit Connection

NOTE: Pay attention to the inserting direction of 74HC595N

5.Project Code

/*

keyestudio STEM Starter Kit

Project 9

Star Wars Laser Rod

http//www.keyestudio.com

*/

int data = 4;// set pin 4 of 74HC595as data input pin SI

int clock = 6;// set pin 6 of 74hc595 as clock pin SCK

int latch = 5;// set pin 5 of 74hc595 as output latch RCK

int ledState = 0;

const int ON = HIGH;

const int OFF = LOW;

void setup()

{

pinMode(data, OUTPUT);

pinMode(clock, OUTPUT);

pinMode(latch, OUTPUT);

}

void loop()

{

for(int i = 0; i < 256; i++)

{

updateLEDs(i);

delay(500);

}

}

void updateLEDs(int value)

{

digitalWrite(latch, LOW);//

shiftOut(data, clock, MSBFIRST, ~value);// serial data “output”, high level first

digitalWrite(latch, HIGH);// latch

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Done uploading!

Put the Laser stick paper card on the LED, you can see 7 LEDs are light one by one, Just like a laser stick full of power.

Project 10: A Small Desktop Lamp

1.Project Introduction

Did you know that you can use Arduino to turn on an LED when you press a button?

In this project, we will use a cartoon lamp card, a button switch and an LED to make a small desk lamp.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Button switch*1 |

Red M5 LED *1 |

10KΩ Resistor*1 |

220Ω Resistor*1 |

|

|

||

Preformed&Flaxible Jumper Wire |

Desk lamp Paper Card*1 |

3.Little Knowledge

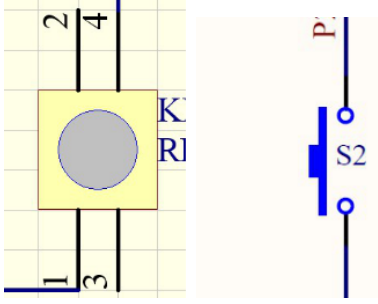

The button is a component that connects two points in a circuit when you press it.

Schematic Diagrams:

4. Circuit Connection

NOTE:

How to connect an LED

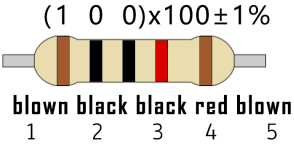

How to identify 5 band 220Ω Resistor and a 5 band 10KΩ Resistor

5.Project Code

/*

keyestudio STEM Starter Kit

Project 10

Small desktop lamp

http//www.keyestudio.com

*/

int ledpin=12;// initialize pin 12

int inpin=5;// initialize pin 5

int val;// define val

void setup()

{

pinMode(ledpin,OUTPUT);// set LED pin as “output”

pinMode(inpin,INPUT);// set button pin as “input”

}

void loop()

{

val=digitalRead(inpin);// read the level value of pin 7 and assign if to val

if(val==LOW)// check if the button is pressed, if yes, turn on the LED

{ digitalWrite(ledpin,LOW);}

else

{ digitalWrite(ledpin,HIGH);}

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Done uploading!Put the lamp card on the button and the LED. When the button is pressed, LED is on, otherwise, LED remains off. In this way, the small desktop lamp project is completed.

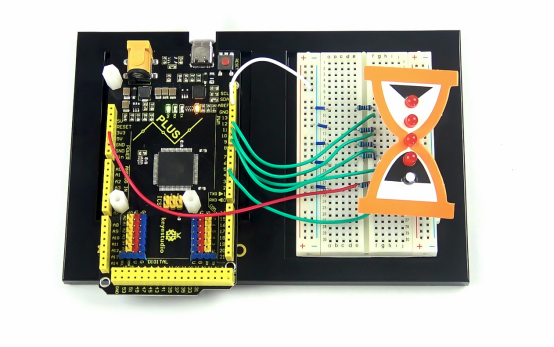

Project 11: Digital Hourglass

1.Project Introduction

Once upon a time, people used hourglasses to measure time.

Today, we DIY a digital hourglass by using a hourglass Paper Card, a Mega Plus Development Board, 5 Red M5 LEDs, a Ball switch.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Ball switch*1 |

Red M5 LED *5 |

10KΩ Resistor*1 |

220Ω Resistor*5 |

|

|

||

Jumper Wire*12 |

hourglass Paper Card*1 |

3.Working Principle

The ball switch is a digital switch. There is a metal ball inside it that can roll. The principle of the metal ball rolling and contacting the guide pin is used to control the on or off of the circuit.

When one end of the switch is below horizontal position, the switch is on. The voltage of the analog port is about 5V (1023 in binary). The LED will be on.

When the other end of the switch is below horizontal position, the switch is off. The voltage of the analog port is about 0V (0 in binary). The LED will be off.

In the program, we determine whether the switch is on or off according to the voltage value of the analog port, whether it’s above 2.5V (512 in binary) or not.

4.Circuit Connection

NOTE:

How to connect an LED

How to identify 5 band 220Ω Resistor and a 5 band 10KΩ Resistor

5.Project Code

/*

keyestudio STEM Starter Kit

Project 11

Digital Hourglass

http//www.keyestudio.com

*/

const byte SWITCH_PIN = 4; // connect tilt switch to D4

byte switch_state = 0;

void setup()

{

for(int i=8;i<12;i++)

{

pinMode(i, OUTPUT);

}

pinMode(SWITCH_PIN, INPUT);

for(int i=8;i<12;i++)

{

digitalWrite(i,0);

}

Serial.begin(9600);

}

void loop()

{

switch_state = digitalRead(SWITCH_PIN);

Serial.println(switch_state);

if (switch_state == 0)

{

for(int i=8;i<12;i++)

{

digitalWrite(i,1);

delay(1000);

}

}

if (switch_state == 1)

{

for(int i=11;i>7;i--)

{

digitalWrite(i,0);

delay(1000);

}

}

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Hold the breadboard with your hands. Tilt to a certain angle, the LEDs will light up one by one. When returning to the previous angle, the LEDs will turn off one by one. Just like an hourglass, the sand leaked out over time.

Project 12: A Guard Dog

1.Project Introduction

PIR sensors measure infrared (IR) light radiating from moving objects that emit heat. The sensor allows you to detect motion of people, animals and cars to trigger security alarms and lighting. They are used to detect movement and are ideal for security and safety such as burglar alarms and security lighting systems.

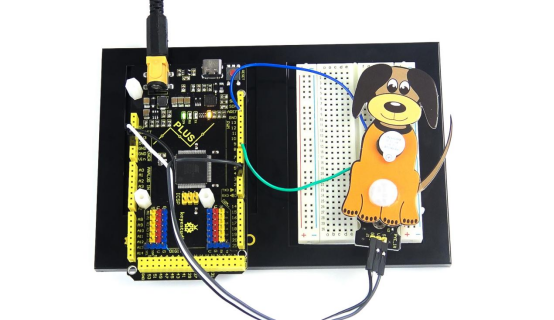

In this project, we will use a PIR motion sensor, a buzzer, and a cartoon dog card to make a guard dog that sounds when someone or an animal moves nearby.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

PIR Motion Sensor*1 |

Passive Buzzer*1 |

Jumper Wire*5 |

Guard dog Paper Card*1 |

3.PIR Motion Sensor Specification

Input Voltage 3.3 ~ 5V (6V Maximum)

Working Current 15uA

Working Temperature -20 ~ 85 ℃

Output Voltage High 3V, Low 0V

Output Delay Time (High Level) About 2.3 to 3 Seconds

Detection Angle 100 °

Detection Distance 7 meters

Output Indicator LED (When output HIGH, it will be ON)

Pin limit Current 100mA

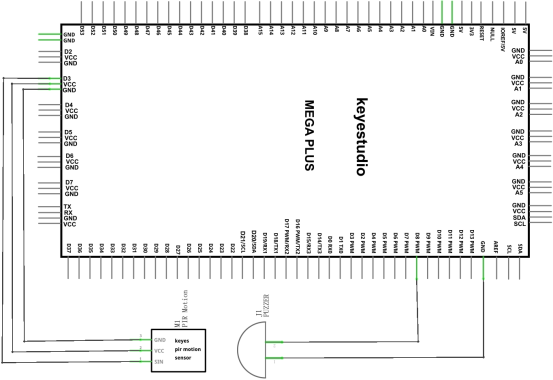

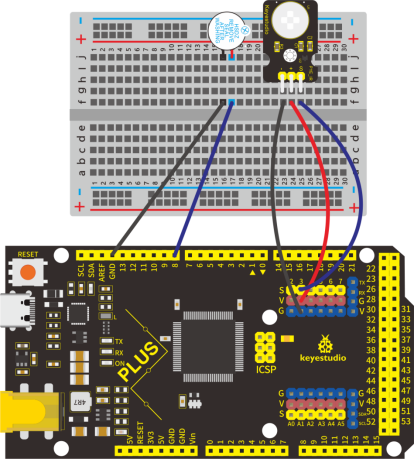

4.Circuit Connection

5.Project Code

/*

keyestudio STEM Starter Kit

Project 12

Guard dog

http//www.keyestudio.com

*/

int buzzerpin = 8; // buzzer pin

int pirPin = 3; // PIR Out pin

int pirStat = 0; // PIR status

void setup() {

pinMode(buzzerpin, OUTPUT);

pinMode(pirPin, INPUT);

Serial.begin(9600);

}

void loop()

{

pirStat = digitalRead(pirPin);

if (pirStat == HIGH)

{ // if motion detected

digitalWrite(buzzerpin, HIGH); // turn buzzer ON

Serial.println("Hey I got you!!!");

}

else {

digitalWrite(buzzerpin, LOW); // turn buzzer OFF if we have no motion

}

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

If the PIR motion sensor detects someone moving nearby, the buzzer will sound an alarm, and click to open the serial monitor on the Arduino IDE, you will see “Hey I got you!!!”.

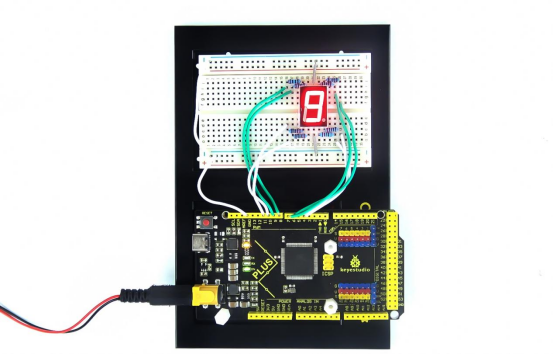

Project 13: DIY a Time Bomb

1.Project Introduction

A seven-segment display is a form of the electronic display device for displaying decimal numerals, they are widely used in digital clocks, electronic meters, basic calculators, and other electronic devices that display numerical information. Even the bombs we saw in the movie have seven-segment displays.

Perhaps seven-segment displays don’t look modern enough for you, but they are alternatives to the more complex dot matrix displays and are easy to use both in limited light conditions and in strong sunlight.

In this project, we will make a simple time bomb with a 1-digit LED Segment Display.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

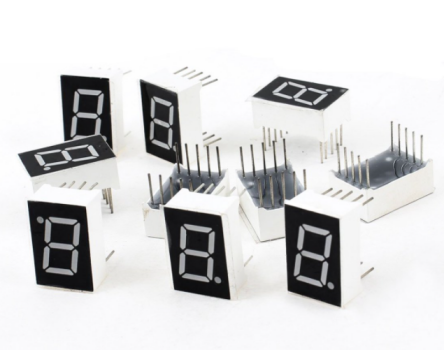

1-digit LED Segment Display*1 |

220Ω Resistor*8 |

Jumper Wire*10+ |

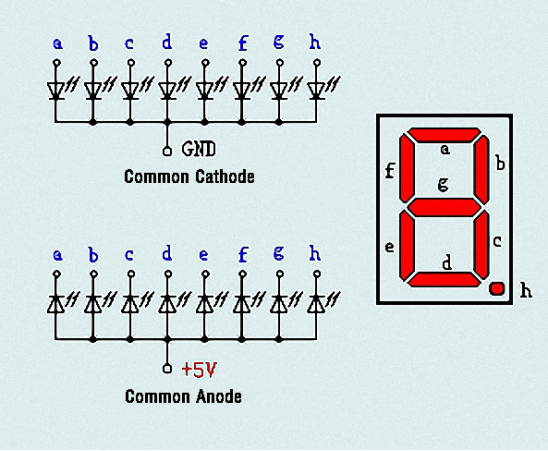

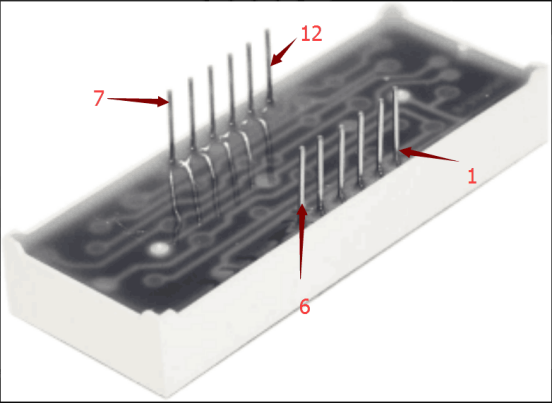

3. 1-digit LED Segment Display principle

LED segment display is a semiconductor light-emitting device. Its basic unit is a light-emitting diode (LED).

LED segment display can be divided into the 7-segment display and 8-segment display according to the number of segments. The 8-segment display has one more LED unit ( for decimal point display) than 7-segment one.

Each segment of the seven segment LED display is an individual LED. According to the wiring method of LED units, LED segment displays can be divided into common anode displays and common cathode displays.

In a Common Cathode seven segment display. All of the cathodes (or negative terminals) of the segment LEDs are connected together. You should connect the common cathode to GND. To turn on a segment, you set its associated pin to HIGH.

In a Common Anode seven segment display, the anodes (positive terminals) of all of the segments are connected together. You should connect the common anode to +5V. To turn on a segment, you set its associated pin to LOW.

Each segment of the display consists of an LED. So when you use it, you also need to use a current-limiting resistor. Otherwise, LED will be burnt out.

In this experiment, we use a common cathode display. As we mentioned above, you should connect the common cathode to GND. To turn on a segment, you set its associated pin to HIGH。

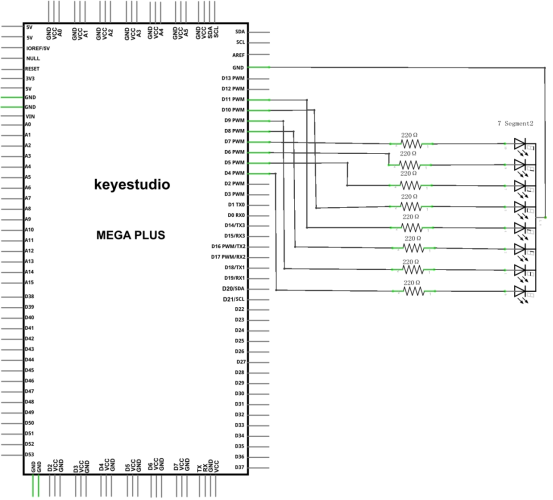

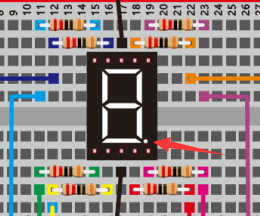

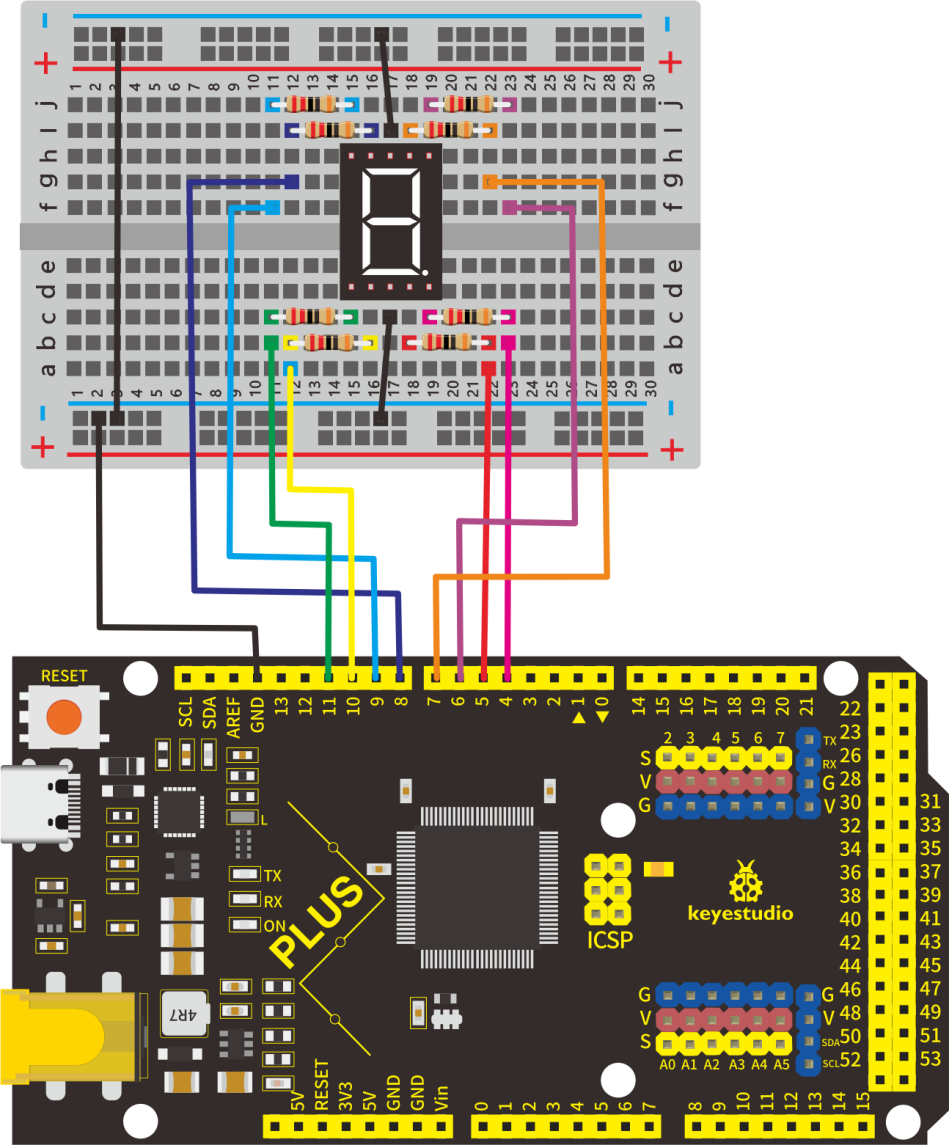

4.Circuit Connection

NOTE:

The direction of the seven-segment display inserted into the panel is consistent with the wiring diagram, and an extra point is in the lower right corner

5.Project Code

There are seven segments for numerical display, one for decimal point display. Corresponding segments will be turned on when displaying certain numbers.

For example, when displaying number 1, b and c segments will be turned on. We compile a subprogram for each number, and compile the main program to display one number every 2 seconds, cycling display number 0 ~ 9.

The displaying time for each number is subject to the delay time, the longer the delay time, the longer the displaying time.

/*

keyestudio STEM Starter Kit

Project 13

Bomb Timer

http//www.keyestudio.com

*/

// set the IO pin for each segment

int a=7;// set digital pin 7 for segment a

int b=6;// set digital pin 6 for segment b

int c=5;// set digital pin 5 for segment c

int d=10;// set digital pin 10 for segment d

int e=11;// set digital pin 11 for segment e

int f=8;// set digital pin 8 for segment f

int g=9;// set digital pin 9 for segment g

int dp=4;// set digital pin 4 for segment dp

void digital_0(void) // display number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e,HIGH);

digitalWrite(f,HIGH);

digitalWrite(g,LOW);

digitalWrite(dp,LOW);

}

void digital_1(void) // display number 1

{

unsigned char j;

digitalWrite(c,HIGH);// set level as “high” for pin 5, turn on segment c

digitalWrite(b,HIGH);// turn on segment b

for(j=7;j<=11;j++)// turn off other segments

digitalWrite(j,LOW);

digitalWrite(dp,LOW);// turn off segment dp

}

void digital_2(void) // display number 2

{

unsigned char j;

digitalWrite(b,HIGH);

digitalWrite(a,HIGH);

for(j=9;j<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

digitalWrite(c,LOW);

digitalWrite(f,LOW);

}

void digital_3(void) // display number 3

{digitalWrite(g,HIGH);

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(dp,LOW);

digitalWrite(f,LOW);

digitalWrite(e,LOW);

}

void digital_4(void) // display number 4

{digitalWrite(c,HIGH);

digitalWrite(b,HIGH);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

digitalWrite(a,LOW);

digitalWrite(e,LOW);

digitalWrite(d,LOW);

}

void digital_5(void) // display number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b, LOW);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e, LOW);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

}

void digital_6(void) // display number 6

{

unsigned char j;

for(j=7;j<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(c,HIGH);

digitalWrite(dp,LOW);

digitalWrite(b,LOW);

}

void digital_7(void) // display number 7

{

unsigned char j;

for(j=5;j<=7;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

for(j=8;j<=11;j++)

digitalWrite(j,LOW);

}

void digital_8(void) // display number 8

{

unsigned char j;

for(j=5;j<=11;j++)

digitalWrite(j,HIGH);

digitalWrite(dp,LOW);

}

void digital_9(void) // display number 5

{

unsigned char j;

digitalWrite(a,HIGH);

digitalWrite(b,HIGH);

digitalWrite(c,HIGH);

digitalWrite(d,HIGH);

digitalWrite(e, LOW);

digitalWrite(f,HIGH);

digitalWrite(g,HIGH);

digitalWrite(dp,LOW);

}

void setup()

{

int i;// set variable

for(i=4;i<=11;i++)

pinMode(i,OUTPUT);// set pin 4-11as “output”

}

void loop()

{

while(1)

{

digital_9();// display number 9

delay(1000); // wait for 1s

digital_8();// display number 8

delay(1000); // wait for 1s

digital_7();// display number 7

delay(1000); // wait for 1s

digital_6();// display number 6

delay(1000); // wait for 1s

digital_5();// display number 5

delay(1000); // wait for 1s

digital_4();// display number 4

delay(1000); // wait for 1s

digital_3();// display number 3

delay(1000); // wait for 1s

digital_2();// display number 2

delay(1000); // wait for 1s

digital_1();// display number 1

delay(1000);// wait for 1s

digital_0();// display number 0

delay(1000);// wait for 1s

}

}

1.Open up the Arduino IDE and copy the above code into a new sketch.

2.Select the correct Board type and COM port for the Arduino IDE.

3.Click Upload button to upload the code.

6.Project Result

Done uploading the code! The LED segment display will show the number from 9 to 0, at this time an interesting time bomb is complete.

Project 14: Hand Counter

1.Project Introduction

4-digit 7-segment LED display is a very practical display device. The display of electronic clocks, the scorer on the court, and the number of people in the park are all needed.

Because of its low price and easy use, more and more projects will use 4-digit 7-segment LED display.

In this project, we use 4-digit 7-segment LED display to make a hand counter.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

4-digit LED Segment Display*1 |

220Ω Resistor*8 |

Jumper Wire*10+ |

Button Switch*1 |

|

|||

10KΩ Resistor*1 |

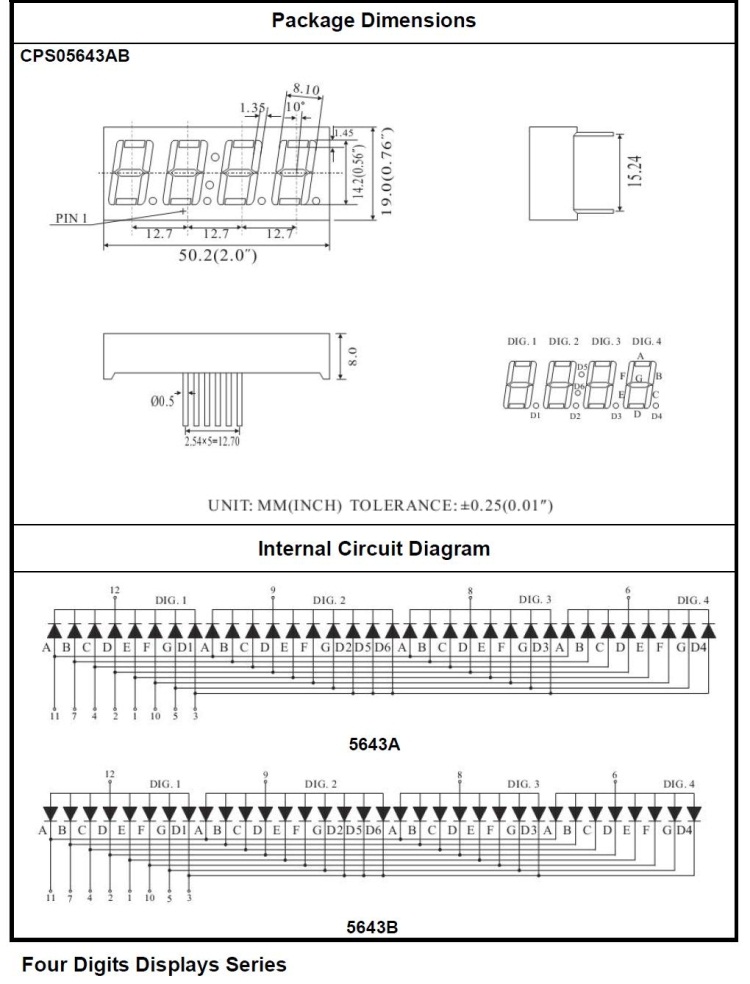

3.The Principle of 4-digit Display

For 4-digit display, there are 12 pins in total. When you place the decimal point downward, the pin on the lower left part is referred to as 1, the upper left part 12.

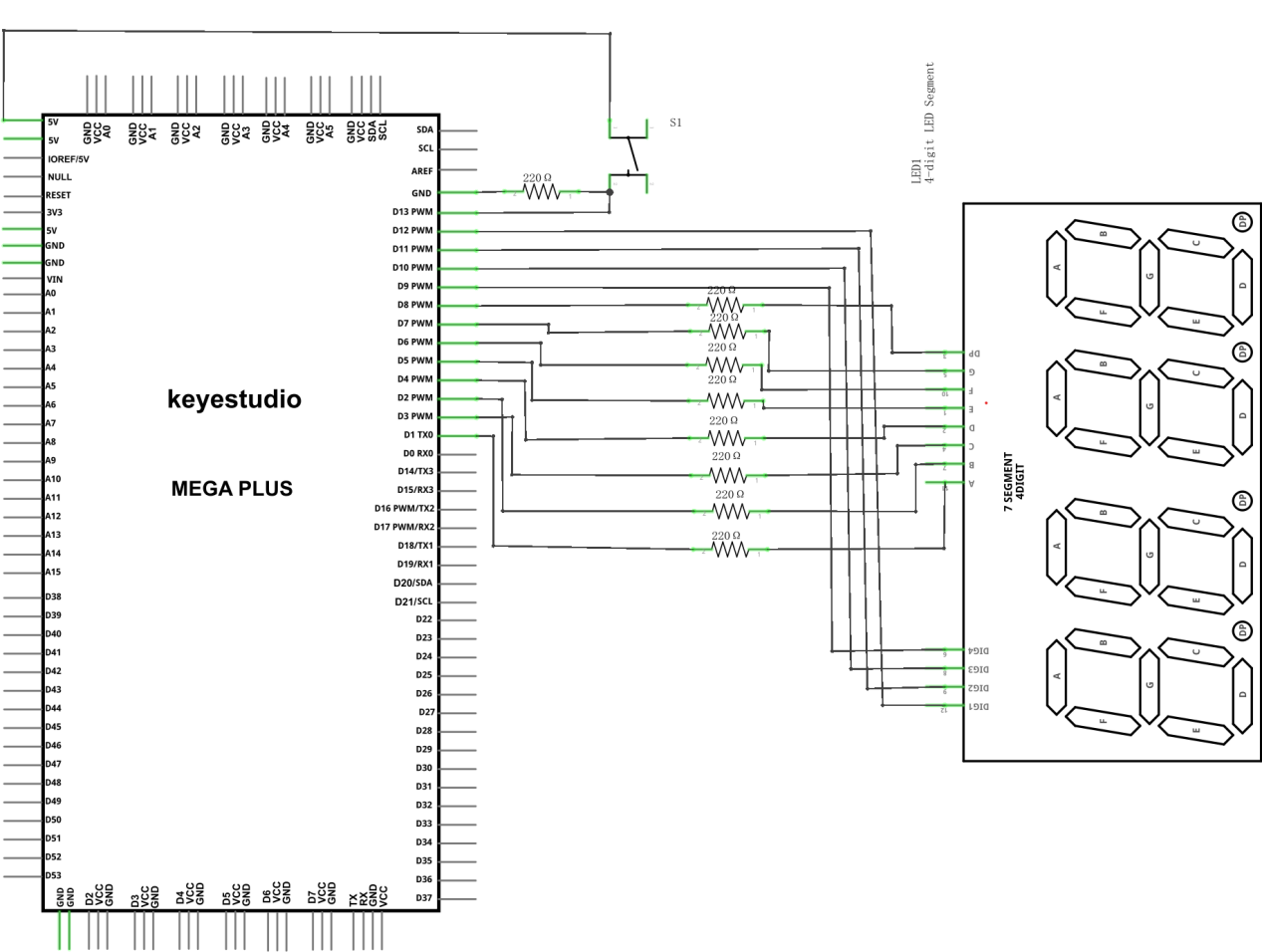

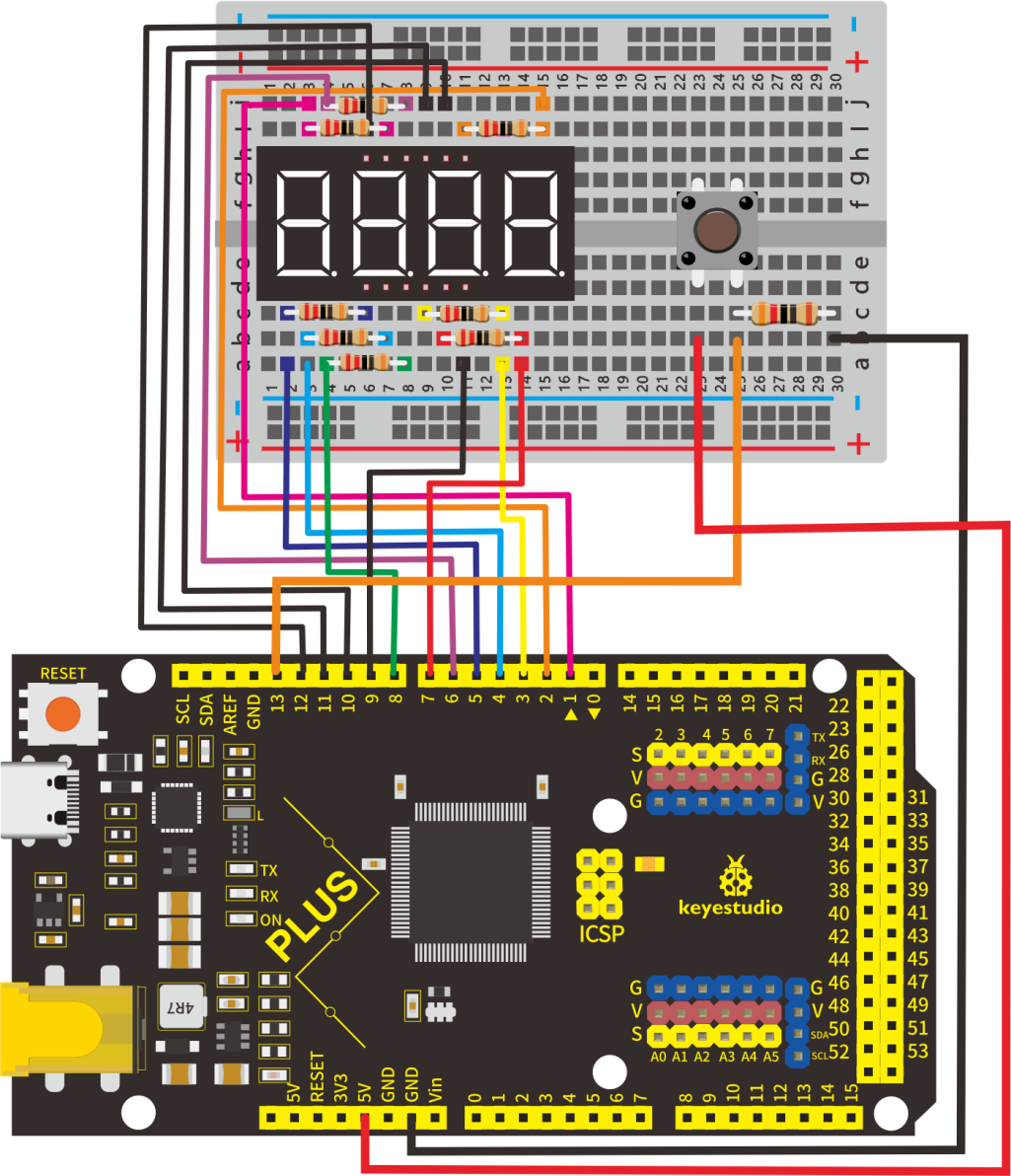

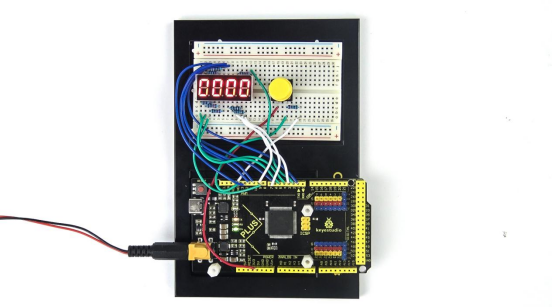

4.Circuit Connection

For LED display, current-limiting resistors are indispensable. Here We use 8 Resistors of 220Ω.

5.Project Code

/*

keyestudio STEM Starter Kit

Project 14

Hand Counter

http//www.keyestudio.com

*/

int a = 1;

int b = 2;

int c = 3;

int d = 4;

int e = 5;

int f = 6;

int g = 7;

int dp = 8;

int d4 = 9;

int d3 = 10;

int d2 = 11;

int d1 = 12;

// set variable

volatile int PushCounter;

volatile int State;

volatile int lastState;

int val1=0;

int val2=0;

int val3=0;

int val4=0;

void setup()

{

pinMode(d1, OUTPUT);

pinMode(d2, OUTPUT);

pinMode(d3, OUTPUT);

pinMode(d4, OUTPUT);

pinMode(a, OUTPUT);

pinMode(b, OUTPUT);

pinMode(c, OUTPUT);

pinMode(d, OUTPUT);

pinMode(e, OUTPUT);

pinMode(f, OUTPUT);

pinMode(g, OUTPUT);

pinMode(dp, OUTPUT);

PushCounter = 0;

State = 0;

lastState = 0;

pinMode(13, INPUT);

}

/////////////////////////////////////////////////////////////

void loop()

{

unsigned long currentMillis = millis();

while(1)

{

while(millis()-currentMillis<100)

{

Display(1, val1);

Display(2, val2);

Display(3, val3);

Display(4, val4);

}

currentMillis = millis();

State = digitalRead(13);

if (State != lastState) {

if (State == 1) {

PushCounter = PushCounter + 1;

if (PushCounter>9999)

{

PushCounter = 0;

}

}

}

lastState = State;

val1=PushCounter/1000;

val2=(PushCounter%1000)/100;

val3=(PushCounter%100)/10;

val4=PushCounter%10;

}

}

///////////////////////////////////////////////////////////////

void WeiXuan(unsigned char n)//

{

switch (n)

{

case 1:

digitalWrite(d1, LOW);

digitalWrite(d2, HIGH);

digitalWrite(d3, HIGH);

digitalWrite(d4, HIGH);

break;

case 2:

digitalWrite(d1, HIGH);

digitalWrite(d2, LOW);

digitalWrite(d3, HIGH);

digitalWrite(d4, HIGH);

break;

case 3:

digitalWrite(d1, HIGH);

digitalWrite(d2, HIGH);

digitalWrite(d3, LOW);

digitalWrite(d4, HIGH);

break;

case 4:

digitalWrite(d1, HIGH);

digitalWrite(d2, HIGH);

digitalWrite(d3, HIGH);

digitalWrite(d4, LOW);

break;

default :

digitalWrite(d1, HIGH);

digitalWrite(d2, HIGH);

digitalWrite(d3, HIGH);

digitalWrite(d4, HIGH);

break;

}

}

void Num_0()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void Num_1()

{

digitalWrite(a, LOW);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void Num_2()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, LOW);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, LOW);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_3()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_4()

{

digitalWrite(a, LOW);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_5()

{

digitalWrite(a, HIGH);

digitalWrite(b, LOW);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_6()

{

digitalWrite(a, HIGH);

digitalWrite(b, LOW);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_7()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void Num_8()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, HIGH);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Num_9()

{

digitalWrite(a, HIGH);

digitalWrite(b, HIGH);

digitalWrite(c, HIGH);

digitalWrite(d, HIGH);

digitalWrite(e, LOW);

digitalWrite(f, HIGH);

digitalWrite(g, HIGH);

digitalWrite(dp, LOW);

}

void Clear() // clear the screen

{

digitalWrite(a, LOW);

digitalWrite(b, LOW);

digitalWrite(c, LOW);

digitalWrite(d, LOW);

digitalWrite(e, LOW);

digitalWrite(f, LOW);

digitalWrite(g, LOW);

digitalWrite(dp, LOW);

}

void pickNumber(unsigned char n)// select number

{

switch (n)

{

case 0: Num_0();

break;

case 1: Num_1();

break;

case 2: Num_2();

break;

case 3: Num_3();

break;

case 4: Num_4();

break;

case 5: Num_5();

break;

case 6: Num_6();

break;

case 7: Num_7();

break;

case 8: Num_8();

break;

case 9: Num_9();

break;

default: Clear();

break;

}

}

void Display(unsigned char x, unsigned char Number)

// take x as coordinate and display number

{

WeiXuan(x);

pickNumber(Number);

delay(1);

Clear() ; // clear the screen

}

//////////////////////////////////////////////////////////

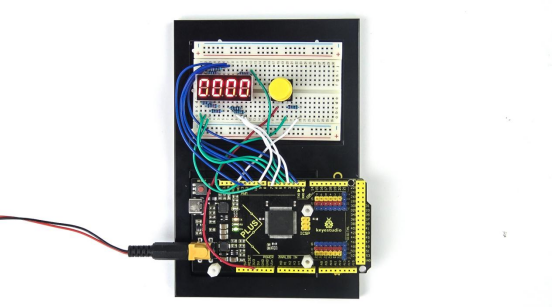

6.Project Result

Upload the project code to the Mega plus development board. At the beginning, the 4-digit digital tube displays 0000. Each time the button is pressed, the number increases by 1. When the number is increased to 9999, press the button again, and the digital tube restarts and displays 0000.

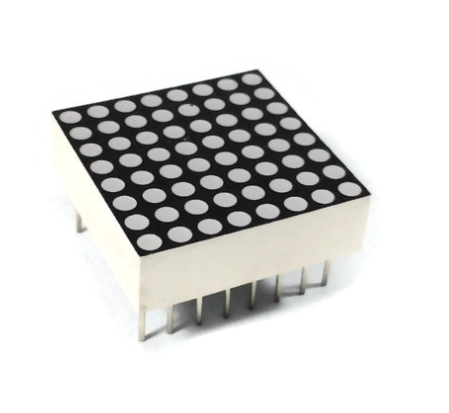

Project 15: Beating Heart

1.Project Introduction

A dot-matrix display is an electronic digital display device that displays information on machines, clocks and watches, public transport departure indicators and many other devices.

In this project, we use a 8x8 LED dot matrix to make a beating heart.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

8*8 Dot Matrix*1 |

220Ω Resistor*8 |

Jumper Wire*10+ |

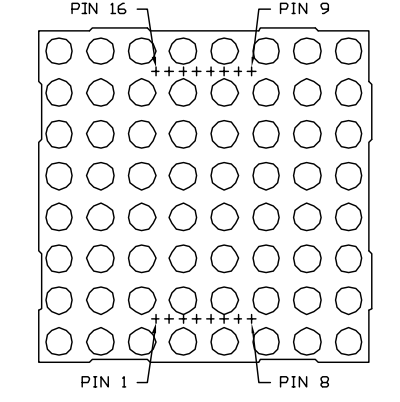

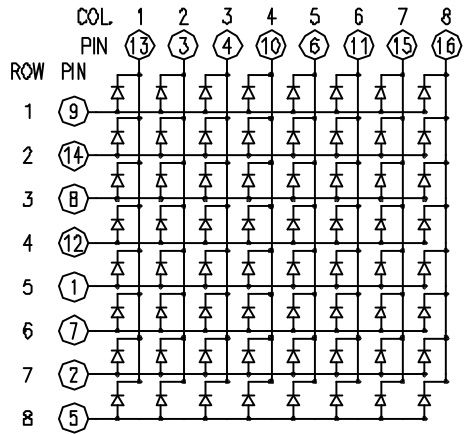

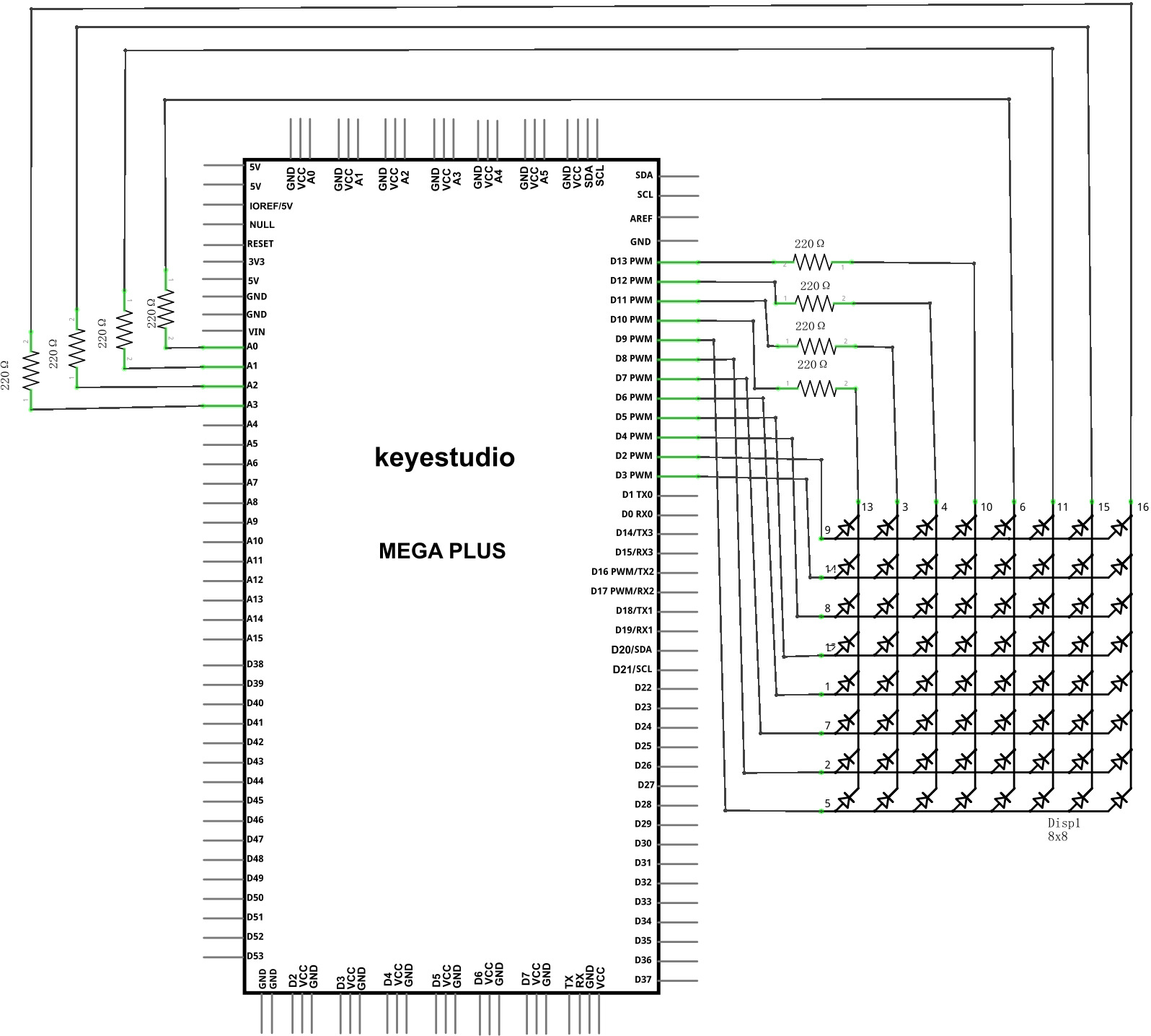

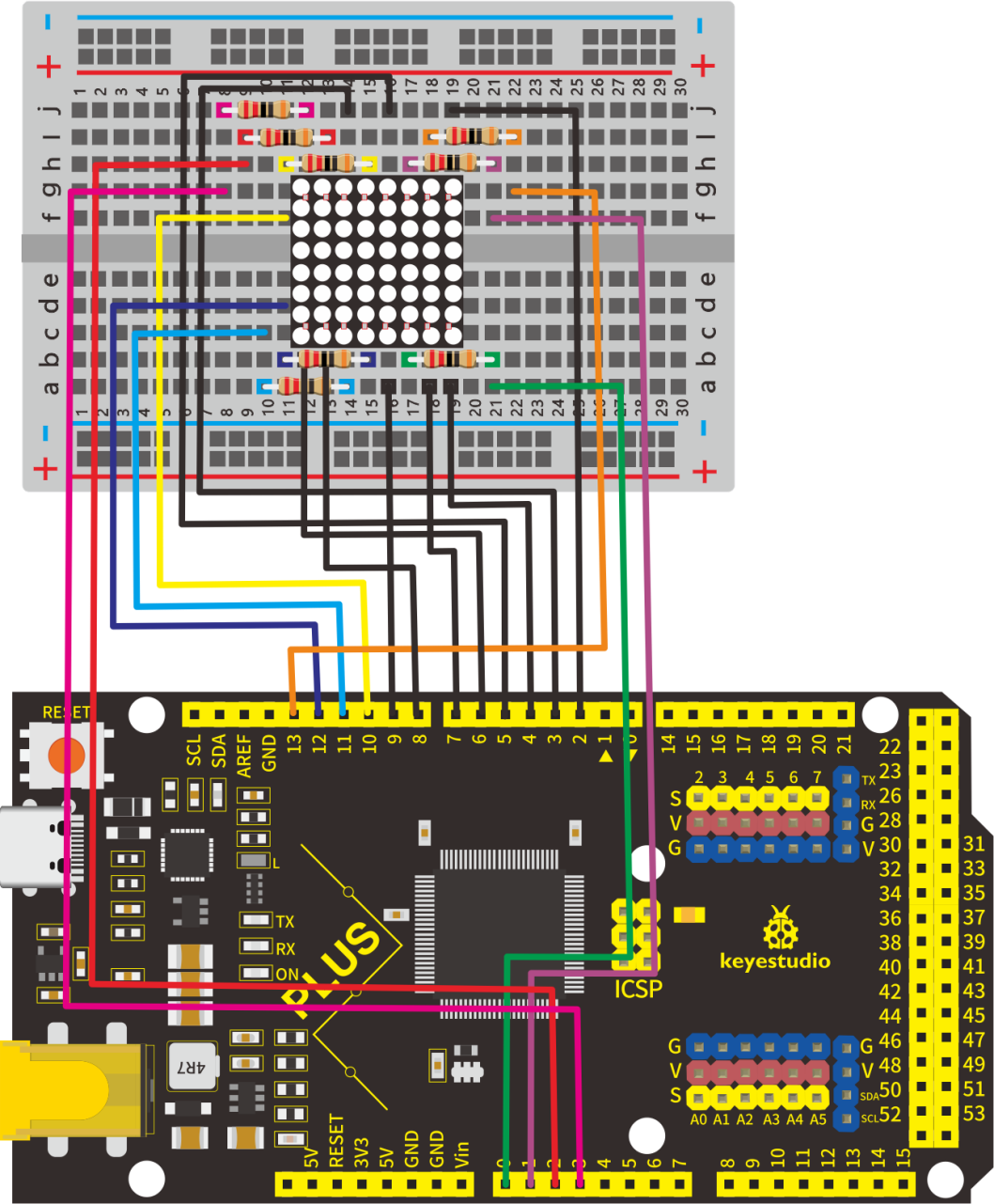

3. Principle of 8*8 dot-matrix

The external view of a dot-matrix is shown as follows

The internal view of a dot-matrix is shown as follows

The 8*8 dot-matrix is made up of sixty-four LEDs, and each LED is placed at the cross point of a row and a column.

When the electrical level of a certain row is 1 and the electrical level of a certain column is 0, the corresponding LED will lighten. If you want to light the LED on the first dot, you should set pin 9 to high level and pin 13 to low level.

If you want to light LEDs on the first row, you should set pin 9 to high level and pins 13, 3, 4, 10, 6, 11, 15 and 16 to low level.

If you want to light the LEDs on the first column, set pin 13 to low level and pins 9, 14, 8, 12, 1, 7, 2 and 5 to high level.

4.Circuit Connection

5.Project Code

/*

keyestudio STEM Starter Kit

Project 15

Beating Heart

http//www.keyestudio.com

*/

// 2-dimensional array of row pin numbers:

int R[] = {2,3,4,5,6,7,8,9};

// 2-dimensional array of column pin numbers:

int C[] = {10,11,12,13,14,15,16,17};

unsigned char biglove[8][8] = //the big "heart"

{

0,0,0,0,0,0,0,0,

0,1,1,0,0,1,1,0,

1,1,1,1,1,1,1,1,

1,1,1,1,1,1,1,1,

1,1,1,1,1,1,1,1,

0,1,1,1,1,1,1,0,

0,0,1,1,1,1,0,0,

0,0,0,1,1,0,0,0,

};

unsigned char smalllove[8][8] = //the small "heart"

{

0,0,0,0,0,0,0,0,

0,0,0,0,0,0,0,0,

0,0,1,0,0,1,0,0,

0,1,1,1,1,1,1,0,

0,1,1,1,1,1,1,0,

0,0,1,1,1,1,0,0,

0,0,0,1,1,0,0,0,

0,0,0,0,0,0,0,0,

};

void setup()

{

// iterate over the pins:

for(int i = 0;i<8;i++)

// initialize the output pins:

{

pinMode(R[i],OUTPUT);

pinMode(C[i],OUTPUT);

}

}

void loop()

{

for(int i = 0 ; i < 100 ; i++) //Loop display 100 times

{

Display(biglove); //Display the "Big Heart"

}

for(int i = 0 ; i < 50 ; i++) //Loop display 50 times

{

Display(smalllove); //Display the "small Heart"

}

}

void Display(unsigned char dat[8][8])

{

for(int c = 0; c<8;c++)

{

digitalWrite(C[c],LOW);//use thr column

//loop

for(int r = 0;r<8;r++)

{

digitalWrite(R[r],dat[r][c]);

}

delay(1);

Clear(); //Remove empty display light

}

}

void Clear()

{

for(int i = 0;i<8;i++)

{

digitalWrite(R[i],LOW);

digitalWrite(C[i],HIGH);

}

}

6.Project Result

Upload the project code to the Mega plus development board,the 8*8 dot matrix screen shows a beating heart.

Project 16: An Expressive Frog

1.Project Introduction

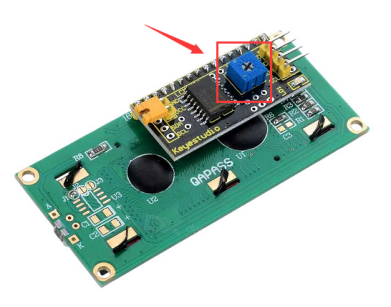

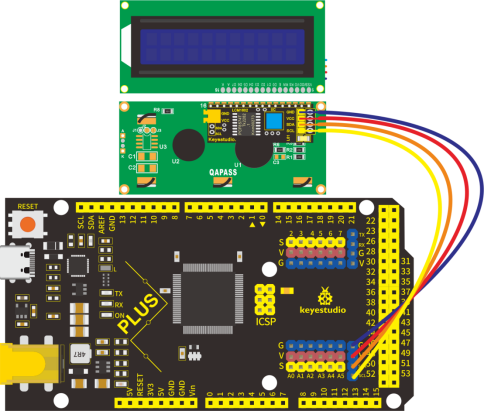

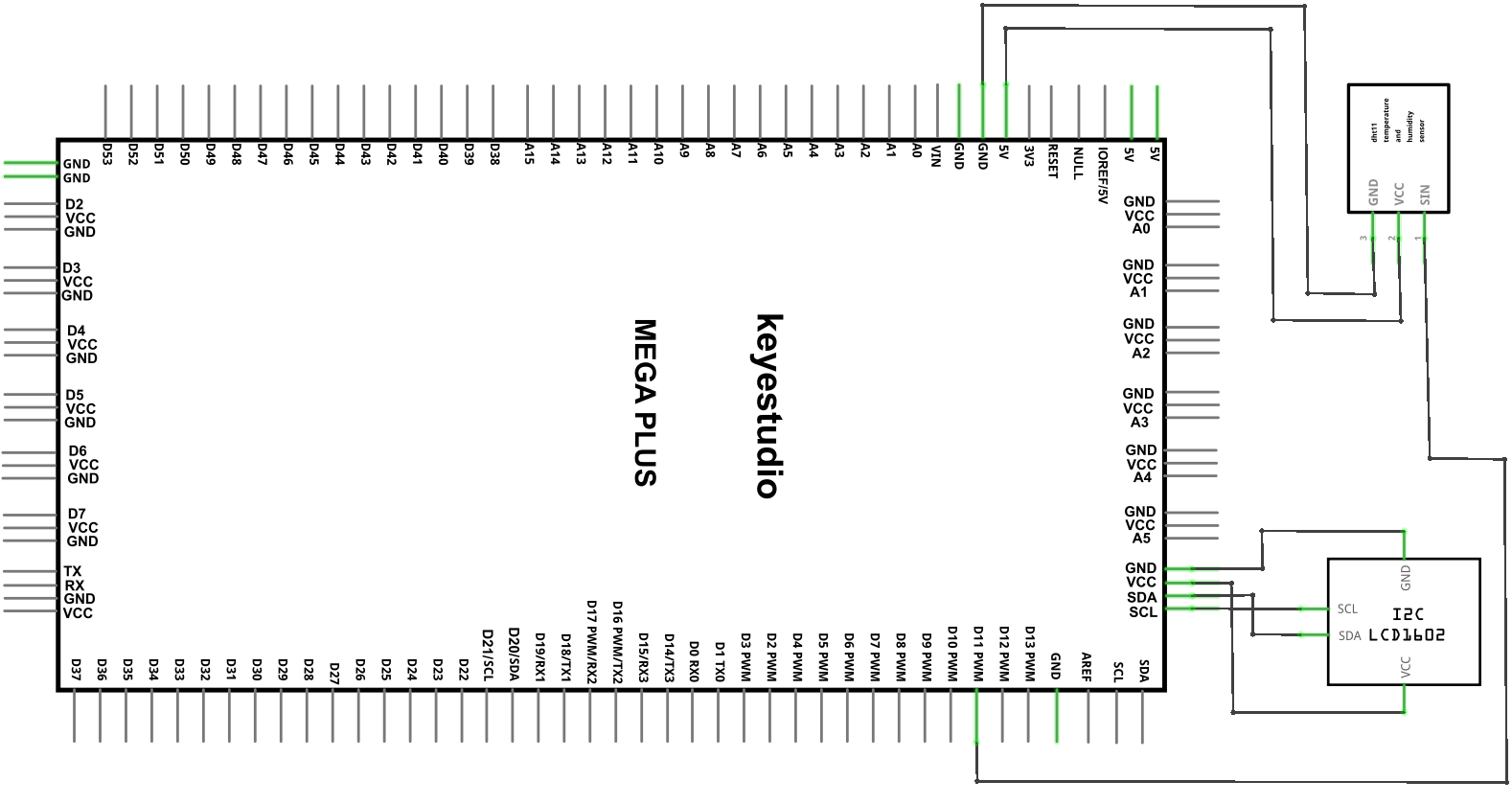

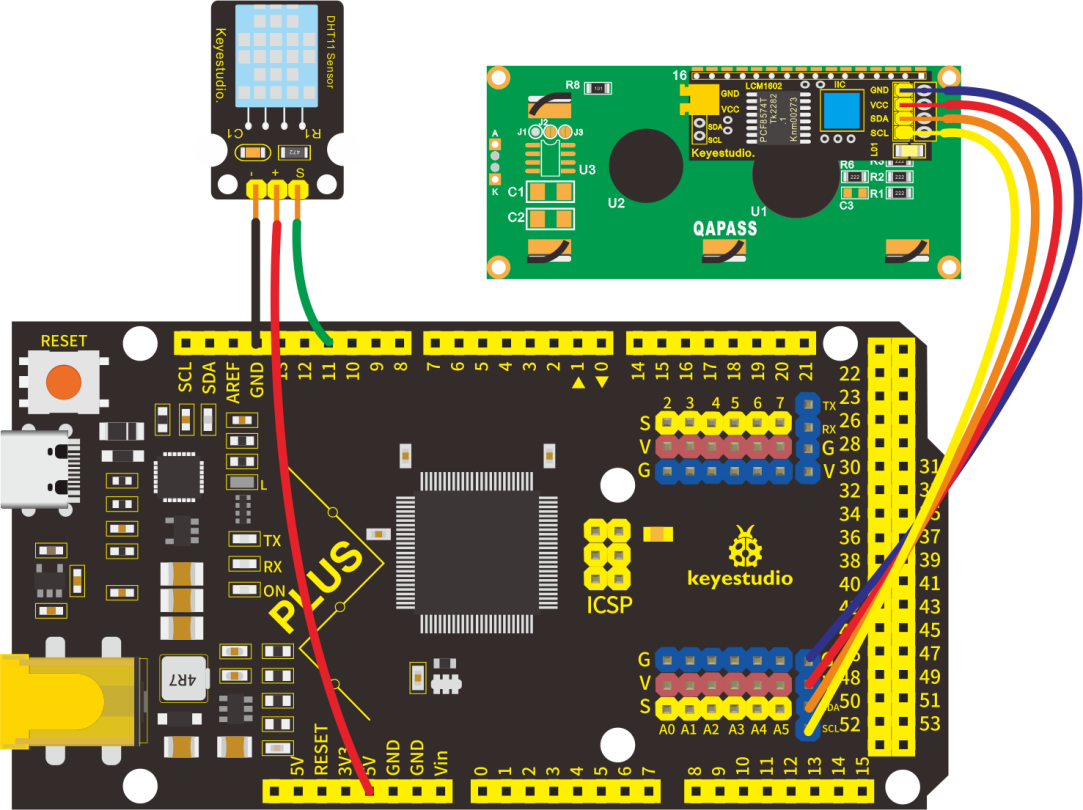

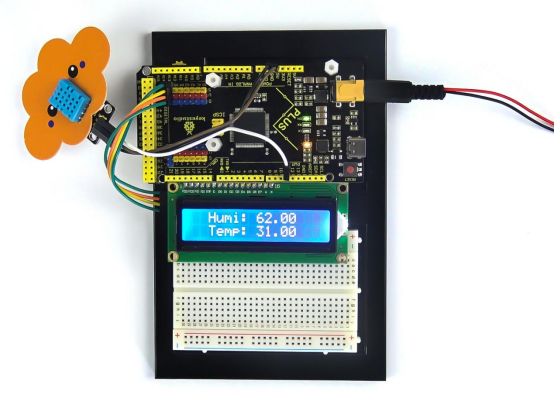

In this project, we will make a frog that can communicate with the outside world and express its emotions in words. Here we use an LCD 1602 display controlled by Arduino.

The ordinary 1602 LCD display needs to occupy 7 IO ports of the control board when working. The 1602 LCD display we provide is equipped with IIC / I2C interface, which will save you 5 IO ports of the control board.

KEYESTUDIO 1602 I2C module is a 16 character by 2 line LCD display with Blue background and White backlight. It is very convenient to use with Arduino Liquid Crystal Library and great for showing letters, numbers, and characters.

On the back of LCD display there is a blue potentiometer. You can turn the potentiometer to adjust the contrast.

(Notice that when you rotate the potentiometer the screen will get brighter or darker, the proper angle will make the font clearer).

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

I2C 1602 LCD*1 |

Jumper Wire*4 |

Cartoon Frog Paper Card*1 |

3.I2C 1602 LCD Parameters

Display capacity 16 * 2 characters

Chip operating voltage 4.5 ~ 5.5V

Working current 2.0mA (5.0V)

Optimum working voltage of the module is 5.0V

Character size 2.95 * 4.35 (W * H) mm

I2C Address:0x27

Backlight (Blue with white char color)

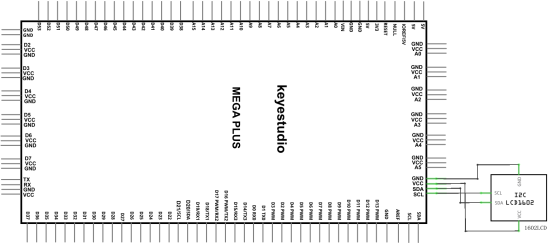

4.Connection

GND: connect to ground

VCC: connect to +5V

SDA: connect to A4

SCL: connect to A5

5.Project Code

/*

keyestudio STEM Starter Kit

Project 16

Frog Display Screen

http//www.keyestudio.com

*/

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x27,16,2); // set the LCD address to 0x27

void setup()

{

lcd.init(); // initialize the lcd

lcd.init();

lcd.backlight();

}

void loop()

{

lcd.setCursor(3,0);

lcd.print("Hello, world!");

lcd.setCursor(2,1);

lcd.print("keyestudio!");

}

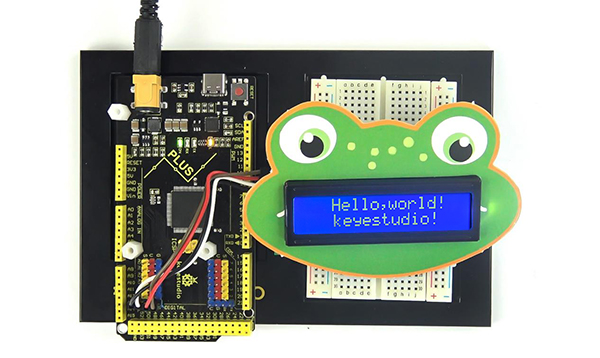

6.Project Result

Upload the project code to the Mega plus development board. LCD1602 will display “Hello, world!”on the first line, “keyestudio!” on the second line.

By changing the text in the brackets of the code we provided and uploading the code again, you can control what the frog will say through the LCD display.

lcd.print(“Hello, world!”);

lcd.setCursor(2,1);

lcd.print(“keyestudio!”);

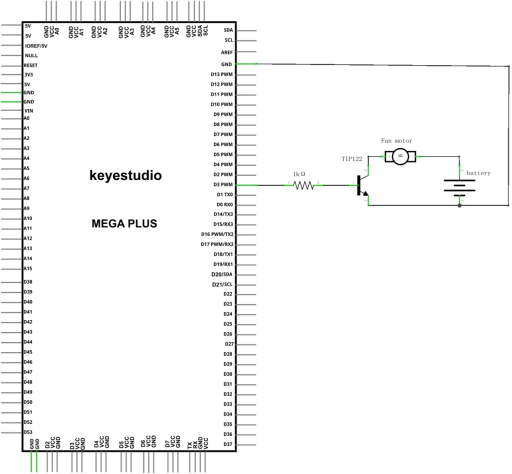

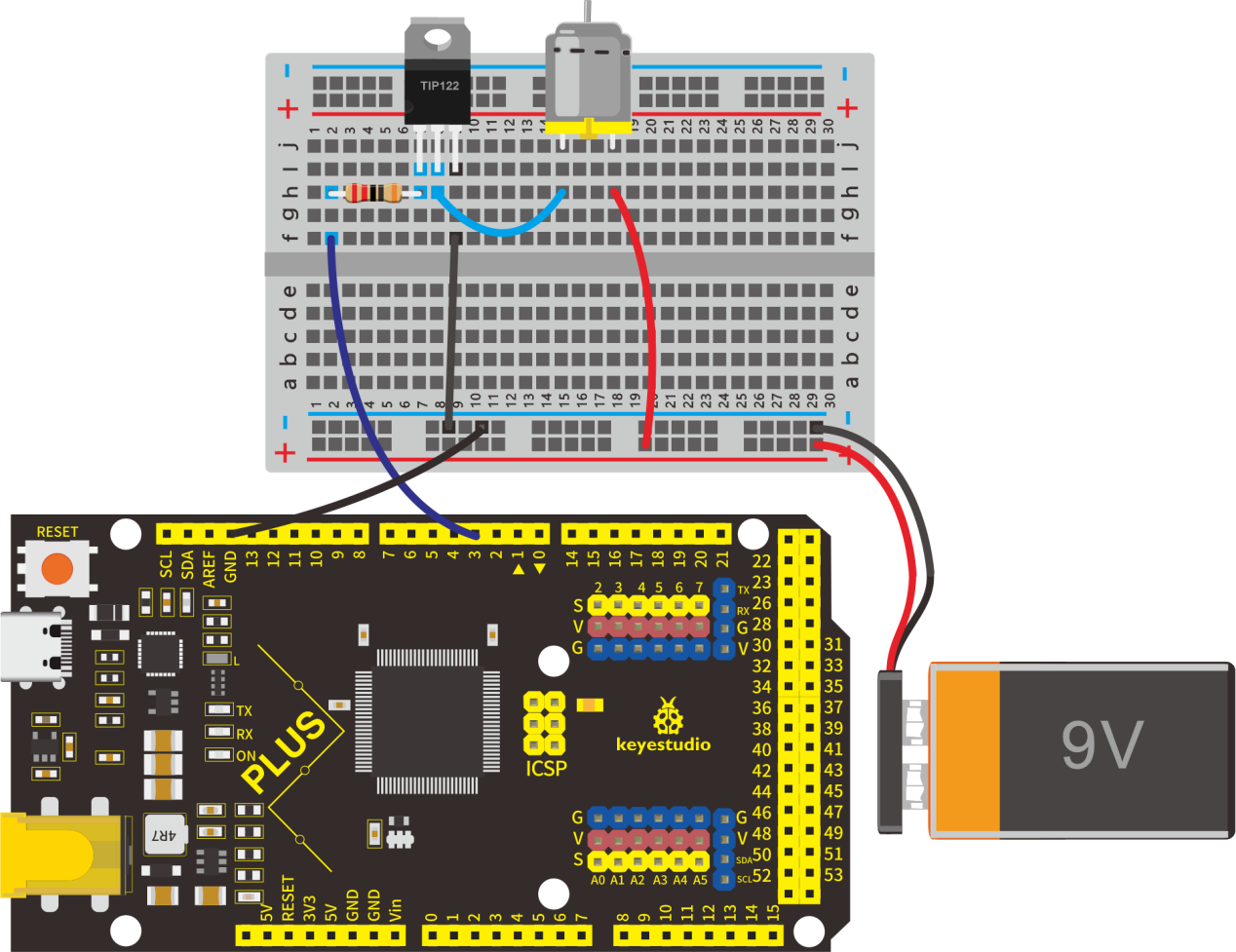

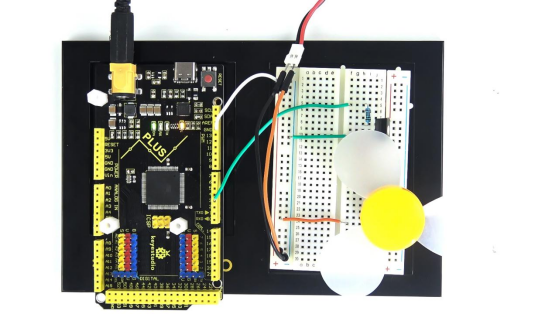

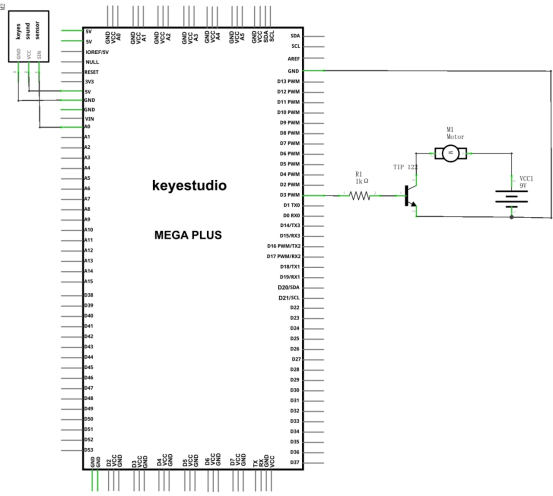

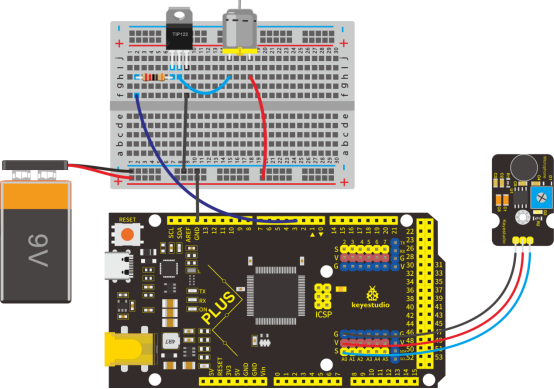

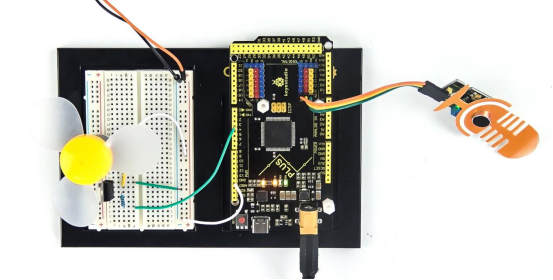

Project 17: Small Fan

1.Project Introduction

Usually, the GPIO pins of Arduino can only provide a maximum current of 40 mA. Since even a small 5V DC motor needs 50 mA or higher current to be driven, it is not recommended to use the Arduino GPIO pins to drive the DC motor.

In this project, we will use a Mega plus Development Board, a TIP122 triode, a motor and small fan leaf to make an electric fan.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

TIP122 Triode*1 |

1 KΩ Resistor *1 |

9V Battery *1 |

9V Battery holder *1 |

|

|

|

|

Fan Motor *1 |

Fan Leaf *1 |

Jumper Wire*10+ |

3.TIP122 Parameters:

Voltage: Vceo: 100V;

Power consumption, Pd: 65W;

Collector DC current: 5A;

DC current gain hFE: 1000;

Package type: TO-220;

Number of pins: 3;

Total power, Ptot: 65W;

Number of transistors: 1;

Transistor type: Power Darlington;

Maximum continuous current, Ic: 5A;

Temperature: 25°C;

Voltage, Vcbo: 100V;

Current, Ic hFE: 3A;

Current, Ic maximum: 5A;

DC current gain hfe, minimum value: 1000;

Surface mount devices: through-hole mounting;

Collector current, average value of Ic: 5A;

Saturation voltage, Vce sat maximum: 2V

4.Connection Diagram

5.Project Code

/*

keyestudio Maker learning kit

Project 17

Small Fan

http//www.keyestudio.com

*/

// the setup function runs once when you press reset or power the board

void setup() {

// initialize digital pin 3 as an output.

pinMode(3, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(3, HIGH); // turn the motor on (HIGH is the voltage level)

delay(2000); // wait for 2 seconds

digitalWrite(3, LOW); // turn the motor off by making the voltage LOW

delay(3000); // wait for 3 second

}

6.Project Result

Upload the project code to the Mega plus development board.

Insert the fan blade into the motor shaft, you will get a small fan that rotates for 2 seconds, and stops for 3 seconds, then restart.

Project 18: Car Speed Dial

1.Project Introduction

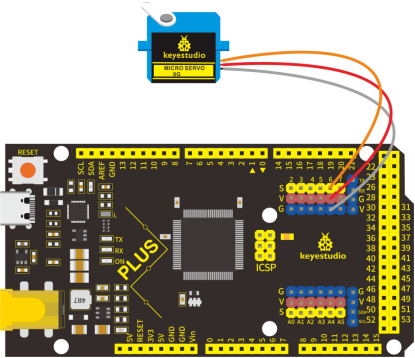

A servo motor is a type of motor that can rotate with great precision. It has been widely used in many applications like toy car, RC helicopters and planes, Robotics, etc.

In this project, we will use a servo motor and a paper card to DIY a car speed dial.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

||

9G Servo Motor*1 |

Car Speed Dial Paper Card*1 |

3. Working Principle of the Servo

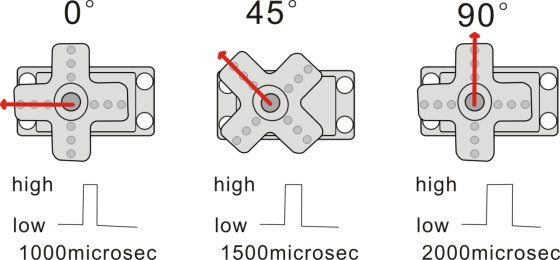

Servo is composed of a rudder disc, position feedback potentiometer, reduction gear set, DC motor, and control circuit. A DC motor drives the reduction gear set, and its output shaft drives a position feedback potentiometer with linear proportional characteristics as position detection. According to the potentiometer feedback voltage, the control circuit compares with the external input control pulse, generates a correction pulse, controls and drives the DC motor to rotate forward or reverse so that the output position of the reduction gear is combined with the desired value. To achieve the purpose of accurately controlling the steering angle.

The control pulse cycle of the servo is 20ms, and the pulse width ranges from 0.5ms to 2.5ms, corresponding to positions from -90 degrees to +90 degrees.

Let us take a 180-degree angle servo as an example:

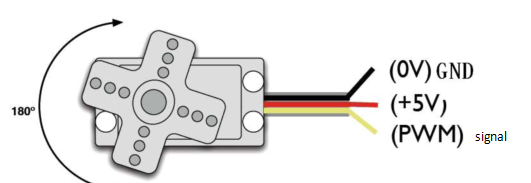

Servo motor comes with many specifications. But all of them have three connection wires, distinguished by brown, red, orange (different brand may have different color).

Brown one is for GND, red one for power positive, orange one for signal line.

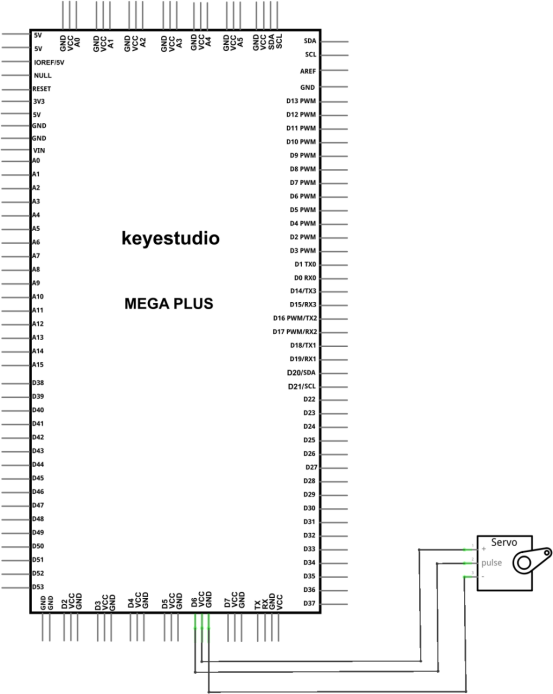

4.Connection Diagram

5.Project Code

/*

keyestudio STEM Starter Kit

Project 18

Car Speed Dial

http//www.keyestudio.com

*/

#include <Servo.h>

Servo myservo;// define servo variable name

void setup()

{

myservo.attach(6);// select servo pin(6 )

}

void loop()

{

myservo.write(0);// set rotate angle of the motor

delay(500);

myservo.write(45);// set rotate angle of the motor

delay(500);

myservo.write(90);// set rotate angle of the motor

delay(500);

myservo.write(135);// set rotate angle of the motor

delay(500);

myservo.write(180);// set rotate angle of the motor

delay(500);

}

6.Project Result

Put the card of the car speed dial to the servo and insert the plastic arm of the servo into the its rotating shaft.

Upload the project code to the Mega plus development board.

The plastic arm of the servo will move at an angle of 0 degrees, 45 degrees, 90 degrees, 135 degrees, and 180 degrees.

A car speed dial model is completed.

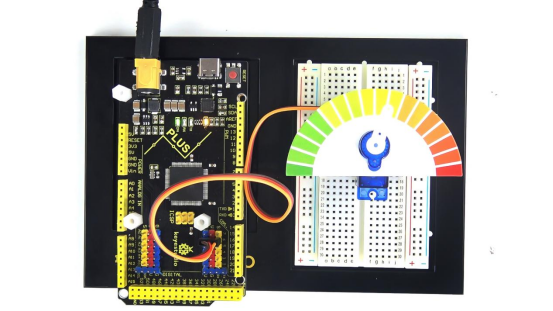

Project 19: Clock Rotation

1.Project Introduction

Stepper motors can be positioned accurately and it is the most important part in industrial robots, 3D printers, large lathes and other mechanical equipment.

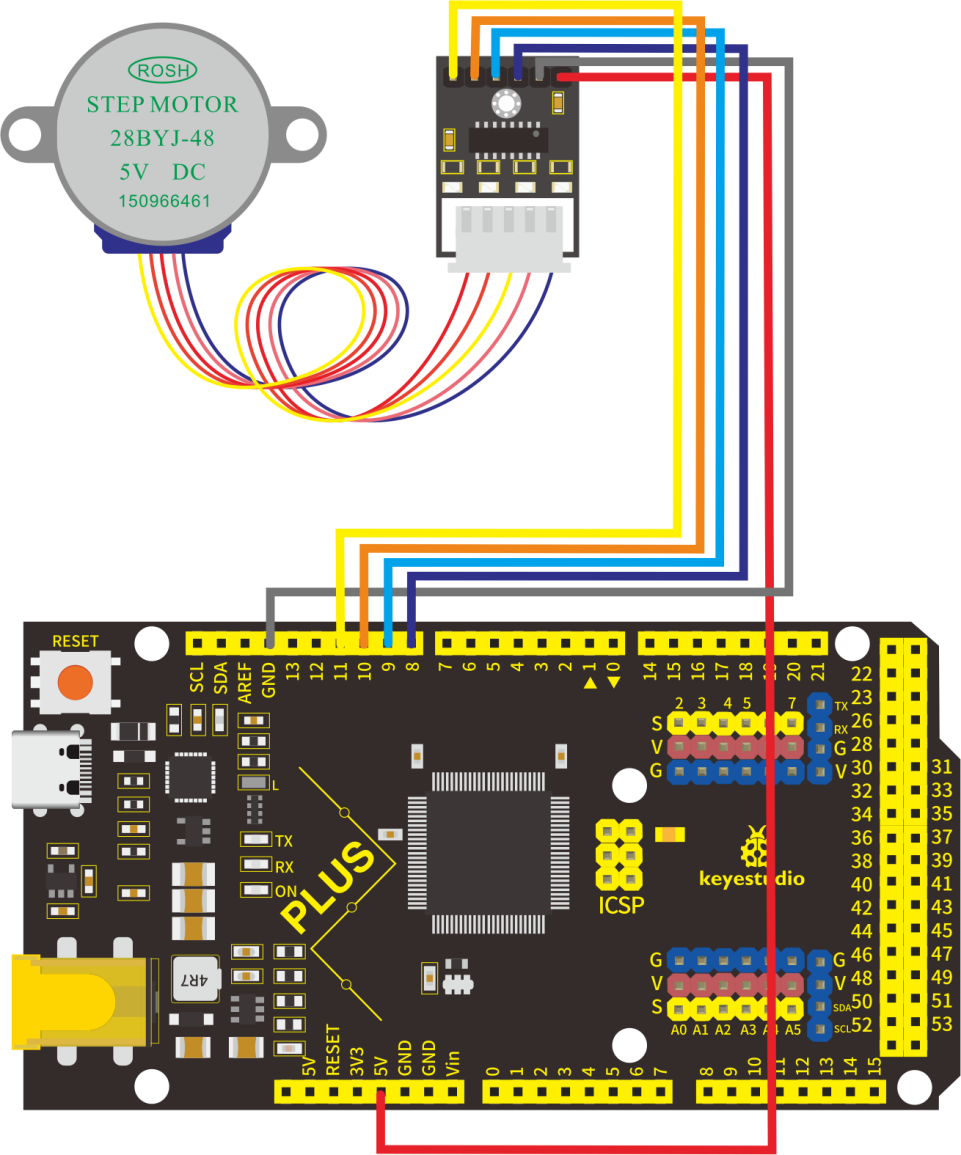

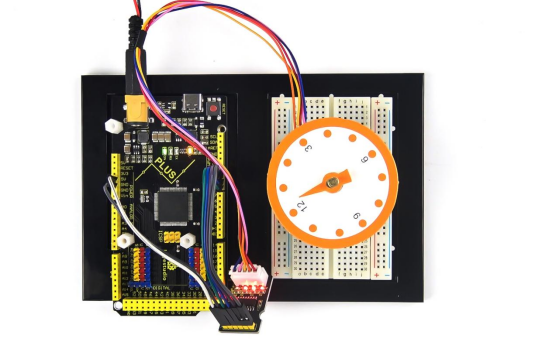

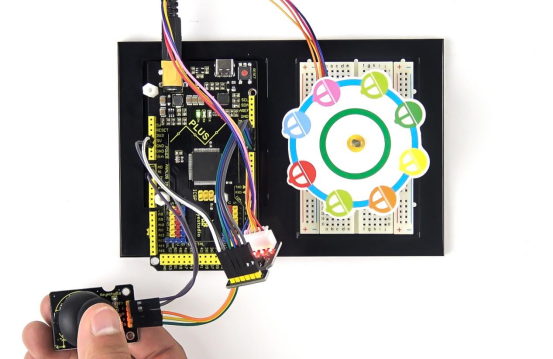

In this project, we will use a stepper motor and a clock paper card to make a clock model.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

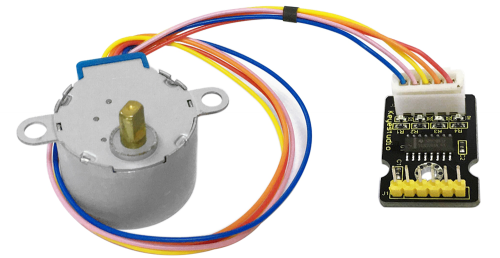

Stepper Motor*1 |

Stepper Motor driver*1 |

Jumper Wire*6 |

Clock Paper Card*1 |

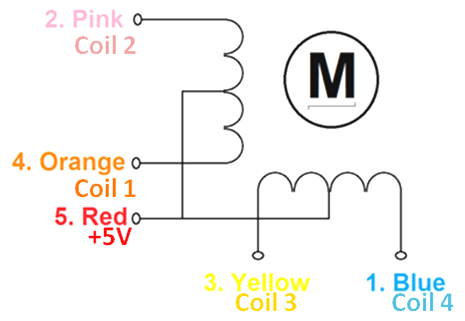

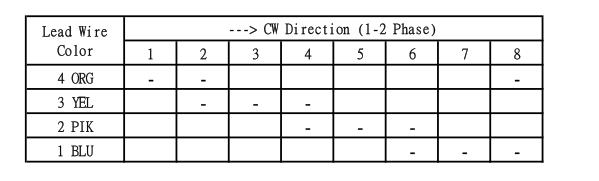

3.Stepper Motor and Driver

Stepper Motor is a motor controlled by a series of electromagnetic coils. It can turn an exact amount of degrees (or steps) as desired, allowing you to move it to an exact location and hold that position. It does so by powering the coils inside the motor for very short periods of time, but you have to power the motor all the time to keep it in the position that you desire.

There are two basic types of stepper motors, unipolar steppers and bipolar steppers.

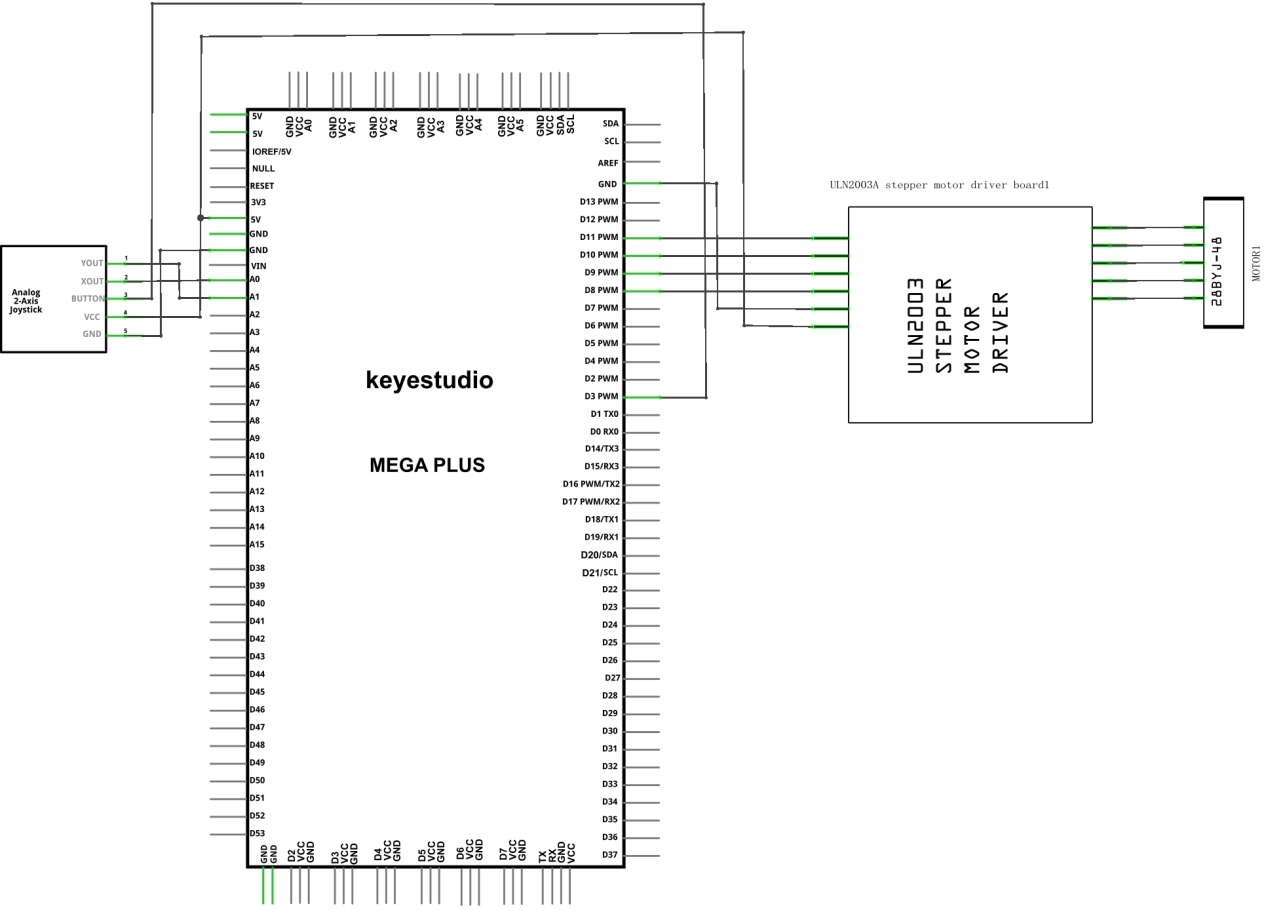

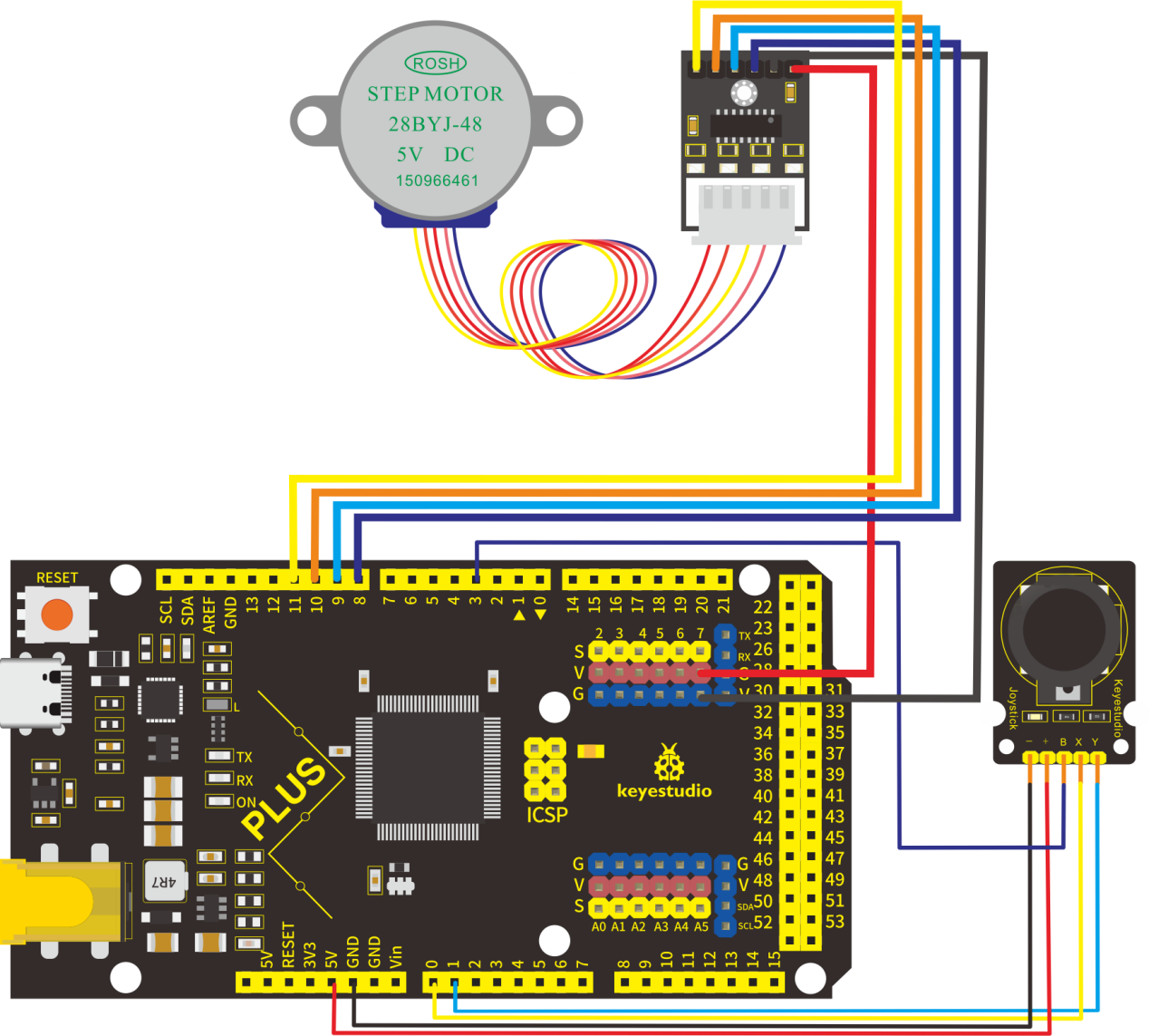

In this lesson, we use a Unipolar Stepper Motor 28-BYJ48.

Unipolar Stepper Motors

A unipolar stepper motor has one winding with a center tap per phase. Each section of windings is switched on for each direction of the magnetic field. Since in this arrangement a magnetic pole can be reversed without switching the direction of the current, the commutation circuit can be made very simple (e.g., a single transistor) for each winding. Typically, given a phase, the center tap of each winding is made common: giving three leads per phase and six leads for a typical two phase motor. Often, these two phase commons are internally joined, so the motor has only five leads.

The simplest way of interfacing a unipolar stepper to Arduino is to use a breakout for ULN2003A transistor array chip. The ULN2003A contains seven darlington transistor drivers and is somewhat like having seven TIP120 transistors all in one package. The ULN2003A can pass up to 500 mA per channel and has an internal voltage drop of about 1V when on. It also contains internal clamp diodes to dissipate voltage spikes when driving inductive loads.

To control the stepper, apply voltage to each of the coils in a specific sequence.

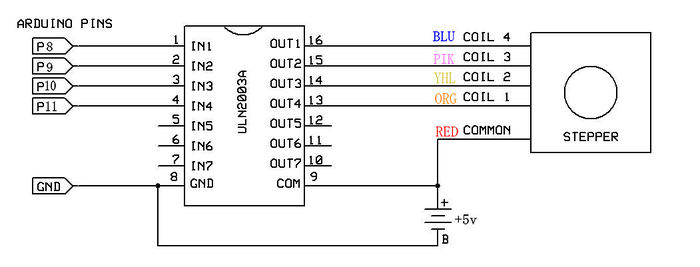

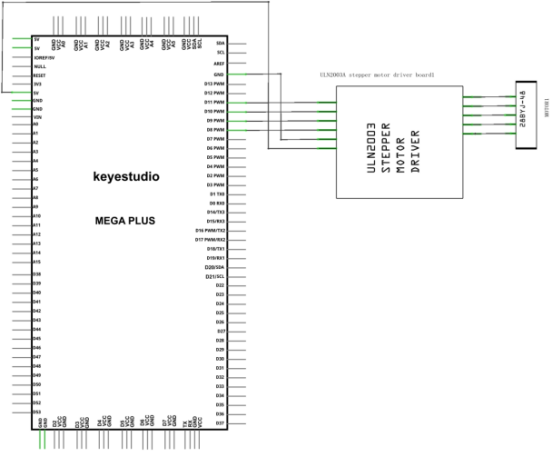

Here are schematics showing how to interface a unipolar stepper motor to four controller pins using a ULN2003A, and showing how to interface using four TIP120’s.

4.Circuit Connection

5.Project Code

/*

keyestudio STEM Starter Kit

Project 19

Analog clock rotation

http//www.keyestudio.com

*/

// Stepper motor pin numbers

const int IN1_pin = 8;

const int IN2_pin = 9;

const int IN3_pin = 10;

const int IN4_pin = 11;

int val;

void setup() {

Serial.begin(9600);

// Arduino pin setup for stepper motor

pinMode(IN1_pin,OUTPUT);

pinMode(IN2_pin,OUTPUT);

pinMode(IN3_pin,OUTPUT);

pinMode(IN4_pin,OUTPUT);

}

void loop() {

int a = 1024;

int b = 1024;

val=Serial.read();

if(val=='A')

{

while(a--)

{

digitalWrite(IN1_pin, HIGH);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN4_pin, LOW);

delay(10);

digitalWrite(IN1_pin, LOW);

digitalWrite(IN2_pin, HIGH);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN4_pin, LOW);

delay(10);

digitalWrite(IN1_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN3_pin, HIGH);

digitalWrite(IN4_pin, LOW);

delay(10);

digitalWrite(IN1_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN4_pin, HIGH);

delay(10);

}

}

if(val=='C')

{

while(b--)

{

digitalWrite(IN4_pin, HIGH);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, LOW);

delay(10);

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, HIGH);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, LOW);

delay(10);

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, HIGH);

digitalWrite(IN1_pin, LOW);

delay(10);

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, HIGH);

delay(10);

}

}

digitalWrite(IN4_pin, LOW);

digitalWrite(IN3_pin, LOW);

digitalWrite(IN2_pin, LOW);

digitalWrite(IN1_pin, LOW);

}

6.Project Result

Upload the code to the Mega plus development board. Open the serial monitor and set the baud rate to 9600, we input A in the serial monitor, the stepper motor is forwarding, and input C in the serial monitor, the stepper motor is reversed.

Project 20: Dimmable Table Lamp

1.Project Introduction

A potentiometer is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider. It work by varying the position of a sliding contact across a uniform resistance. In a potentiometer, the entire input voltage is applied across the whole length of the resistor, and the output voltage is the voltage drop between the fixed and sliding contact.

In this project, we are going to learn how to use Arduino to read the value of the potentiometer, and make a dimmable table lamp.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Potentiometer *1 |

Red M5 LED *1 |

220Ω Resistor*1 |

Jumper Wire*6 |

|

|||

Table Lamp Paper Card*1 |

3.Potentiometer Features

Adjustable potentiometer is a kind of resistor and an analog electronic component, which has two states of 0 and 1(high level and low level). The analog quantity is different, its data state presents a linear state such as 1 to 1000.

4.Read Potentiometer Value

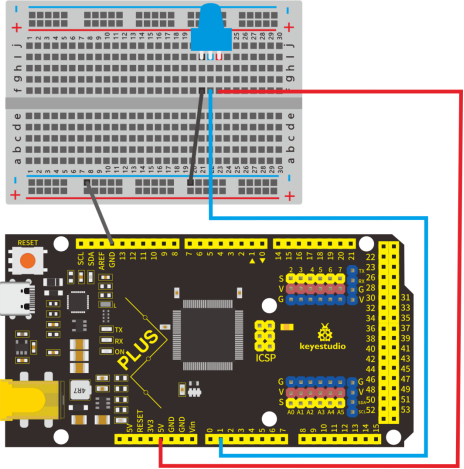

We connect the Adjustable potentiometer to the analog pin of Arduino to read its value. Please refer to the following wiring diagram for wiring.

/*

keyestudio STEM Starter Kit

Project 20.1 Read Potentiometer Value

http//www.keyestudio.com

*/

int potpin=A1;// initialize analog pin A1

int val=0;// define val, assign initial value 0

void setup()

{

Serial.begin(9600);// set baud rate at 9600

}

void loop()

{

val=analogRead(potpin);// read the analog value of analog pin 1, and assign it to val

Serial.println(val);// display val’s value

}

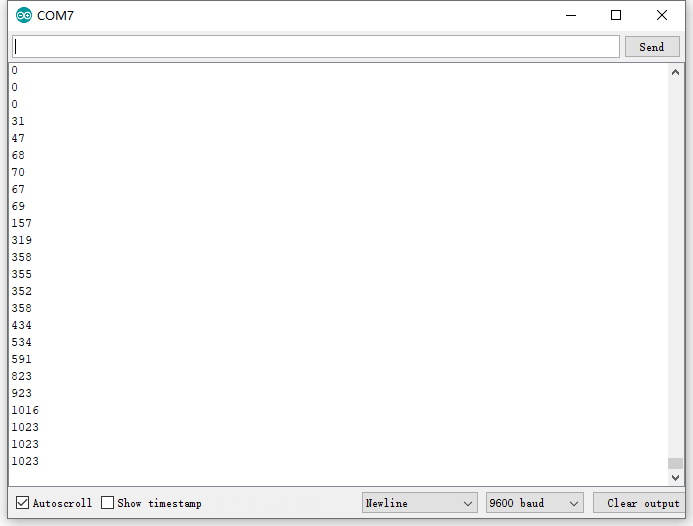

When you rotate the potentiometer knob, you can see the displayed value change. The reading of analog value is a very common function since most sensors output analog value. After calculation, you can get the corresponding value you need.

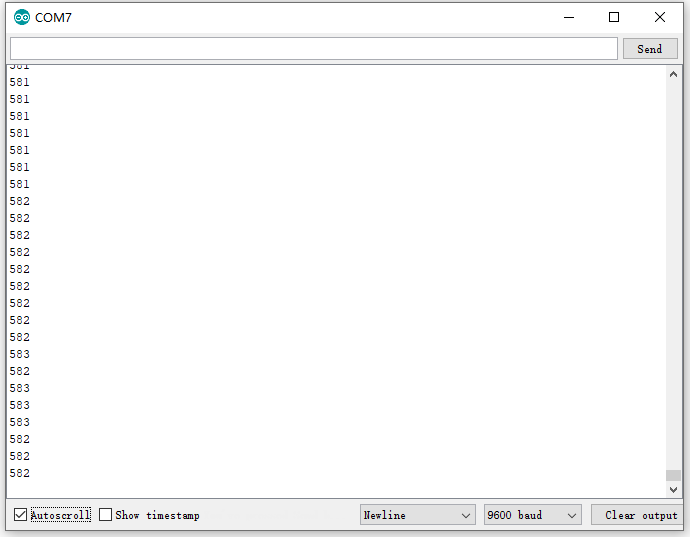

Below figure shows the analog value it reads.

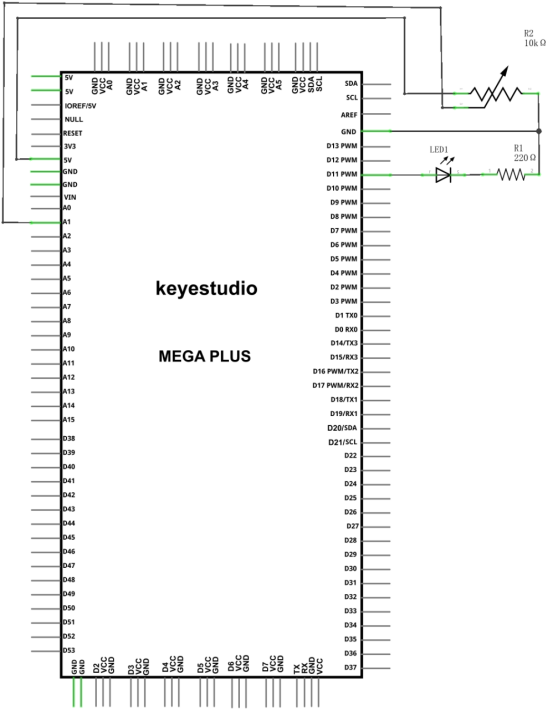

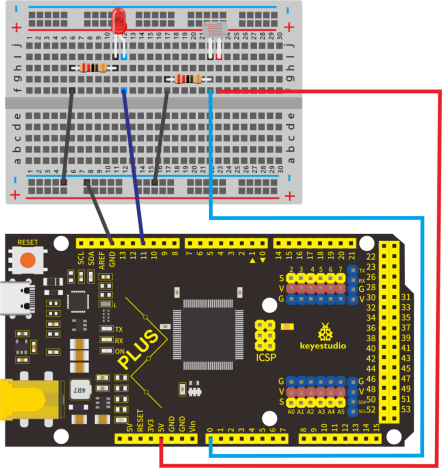

5.Dimming Table Lamp Circuit Connection

In the last step, we read the value of the potentiometer, and now we need to convert the value of the potentiometer into the brightness of the LED to make a small desk lamp with adjustable brightness. See the wiring diagram.

6.Project Code

/*

keyestudio STEM Starter Kit

Project 20.2

Dimming Table Lamp

http//www.keyestudio.com

*/

int potpin=A1;// initialize analog pin A1

int ledpin=11;// initialize digital pin 11

int val=0;// define val, assign initial value 0

void setup()

{

pinMode(ledpin,OUTPUT);// set digital pin as “output”

Serial.begin(9600);// set baud rate at 9600

}

void loop()

{

val=analogRead(potpin);// read the analog value of analog pin 1, and assign it to val

analogWrite(ledpin,val/4);

Serial.println(val);// display val’s value

}

7.Project Result

Put the lamp paper card on the potentiometer and the led. Upload the code to the Mega plus development board.

Open the serial monitor, set the baud rate to 9600, and the monitor will display the value of potentiometer.

When we turn the potentiometer, the brightness of the LED will change. A model of a small desk lamp equipped with an adjustable brightness switch is completed.

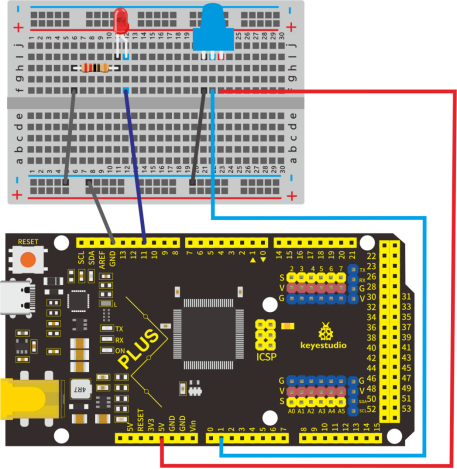

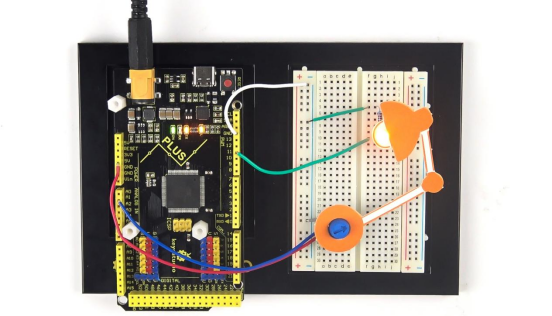

Project 21: Flame Alarm

1.Project Introduction

Fire is one of the terrible disasters, and Fire Alarm Systems are very useful in houses, commercial building, and factories.

In this project, we will use the flame sensor and buzzer to make a fire alarm device. This is a meaningful maker activity.

2.Project Hardware

|

|

|

|

|---|---|---|---|

Mega Plus Development Board*1 |

Plus Board Holder |

400-Hole Breadboard |

USB Cable*1 |

|

|

|

|

Flame Sensor *1 |

Buzzer *1 |

10KΩ Resistor*1 |

Jumper Wire*7 |

|

|||

Fire Alarm Paper Card*1 |

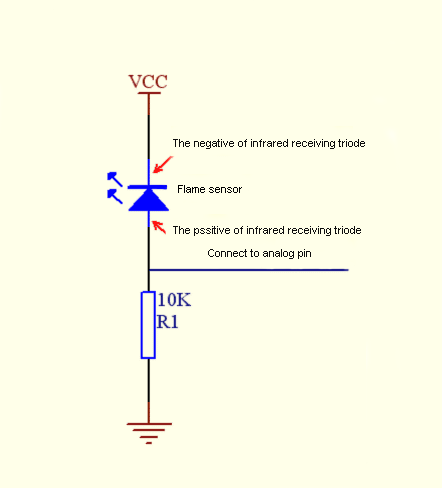

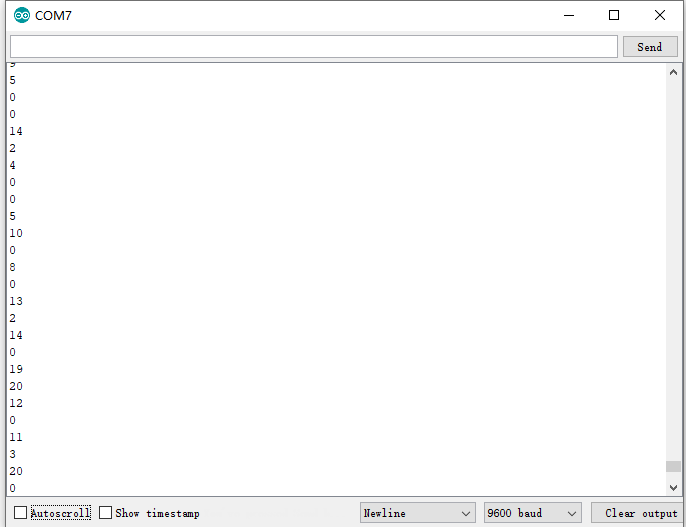

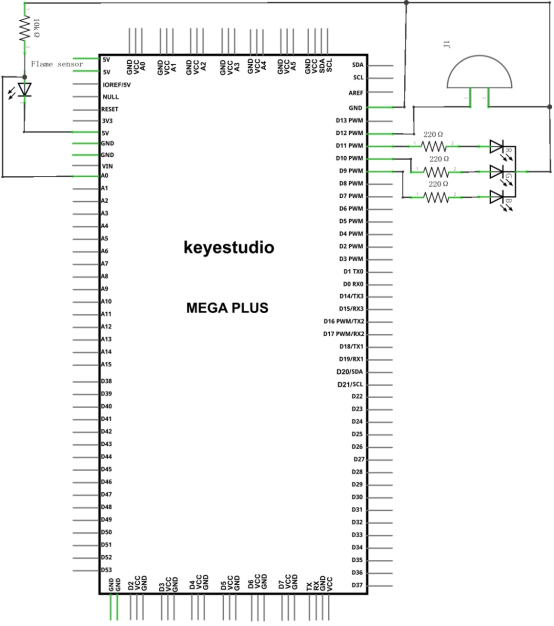

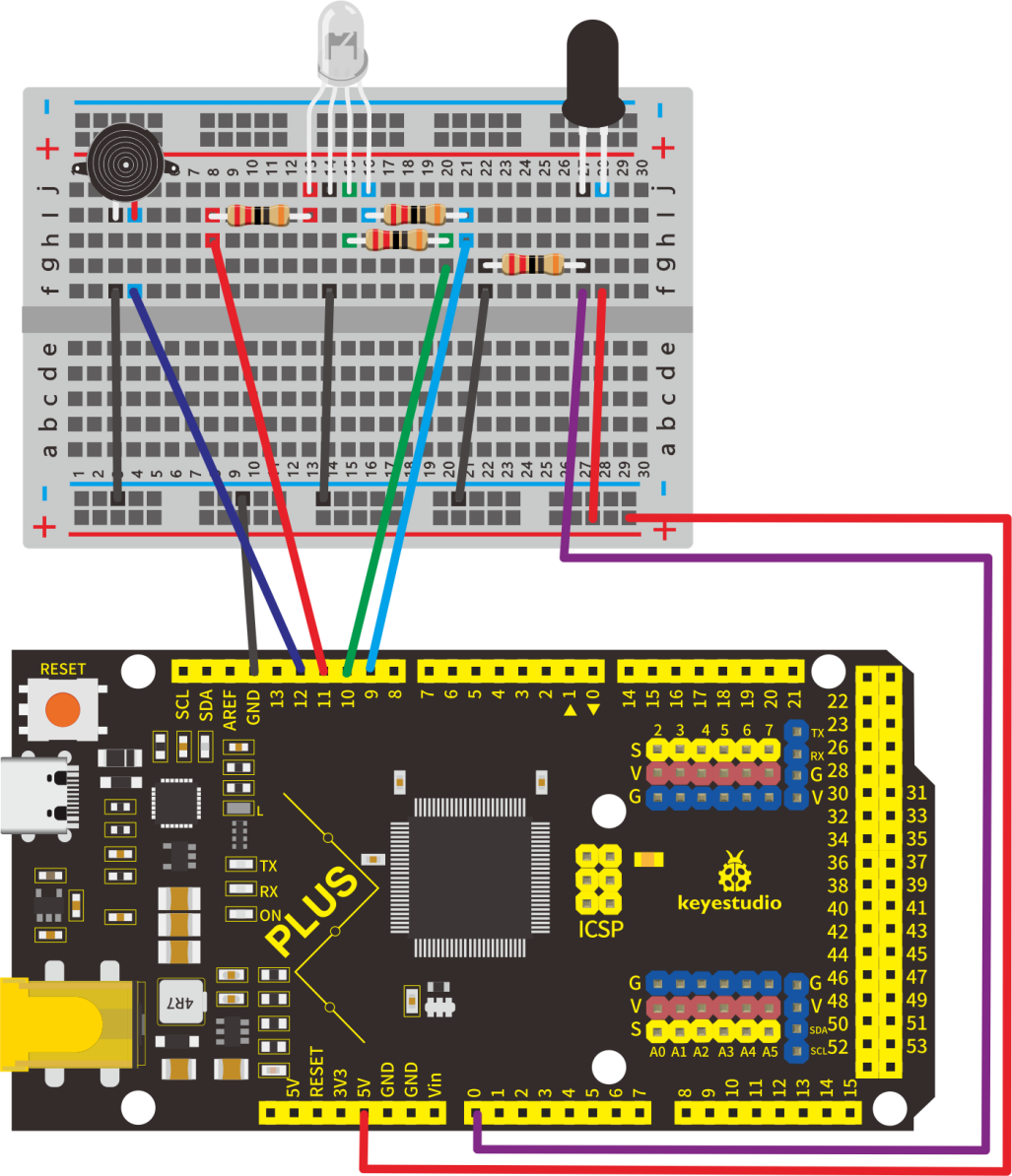

3.Little Knowledge

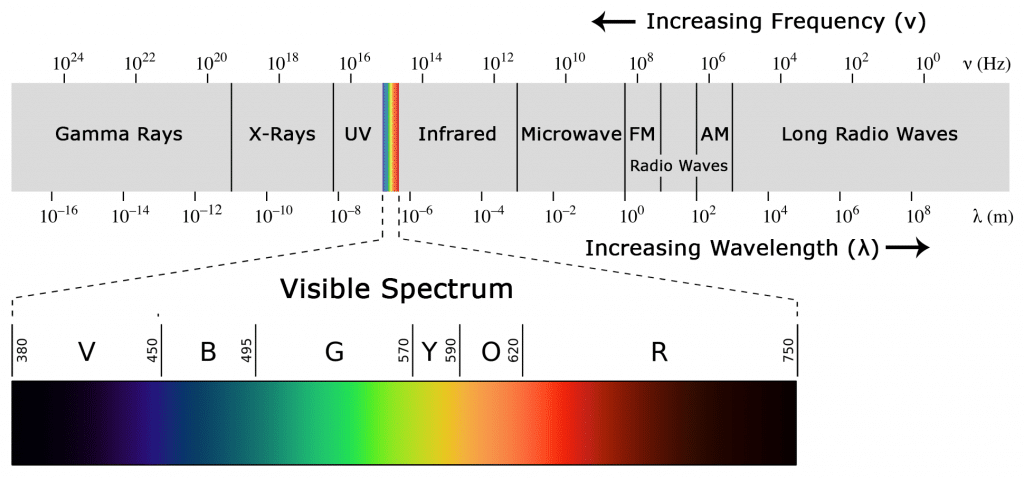

The flame will emit some level of IR light, this light is not visible to human eyes but our flame sensor can detect it and alert a microcontroller like Arduino that a fire has been detected. It has an infrared receiving tube specially designed to detect fire, and then to convert the flame brightness into fluctuating level signal.

The shorter lead of the receiving triode is negative, the other one is positive. We should connect negative to 5V pin, connect positive to an analog pin, a resistor, and GND. As shown below

4.Read Flame Sensor Value

We first use a simple code to read the value of the flame sensor, print it in the serial monitor.

Project code

/*

keyestudio STEM Starter Kit

Project 21.1

Read Flame Sensor Value

http//www.keyestudio.com

*/

int flamepin=0;// initialize analog pin 0

int val=0;// define val, assign initial value 0

void setup()

{

Serial.begin(9600);// set baud rate at 9600

}

void loop()

{

val=analogRead(flamepin);// read the analog value of analog pin 0, and assign it to val

Serial.println(val);// display val’s value

}

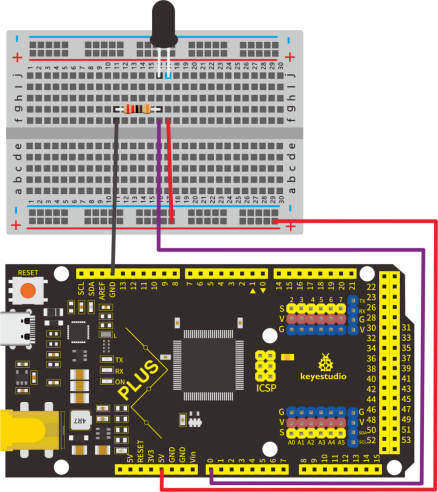

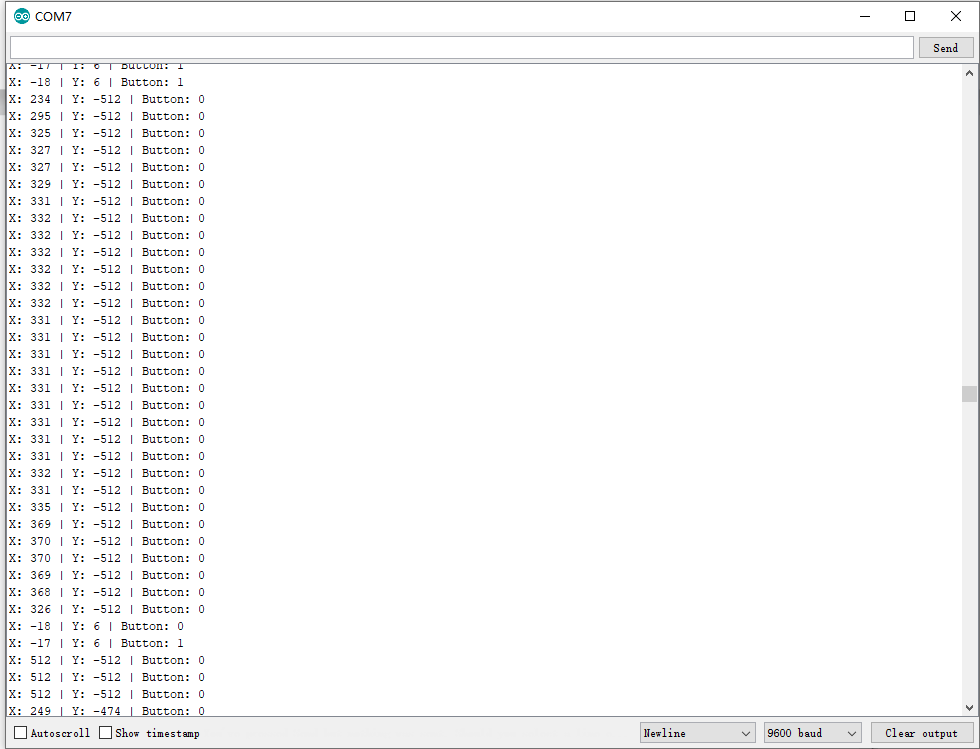

Upload the code to the Mega plus development board, open the serial monitor, and use a lighter to approach the flame sensor to see the value.

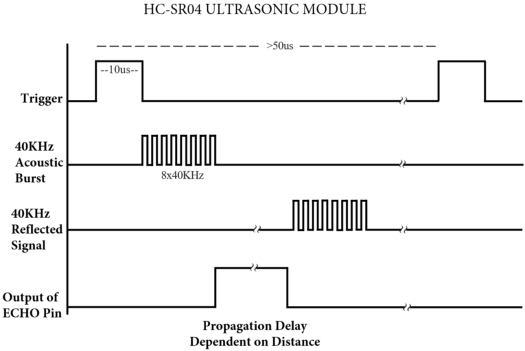

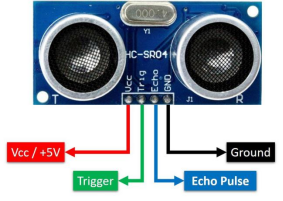

5.Flame Alarm Circuit Connection